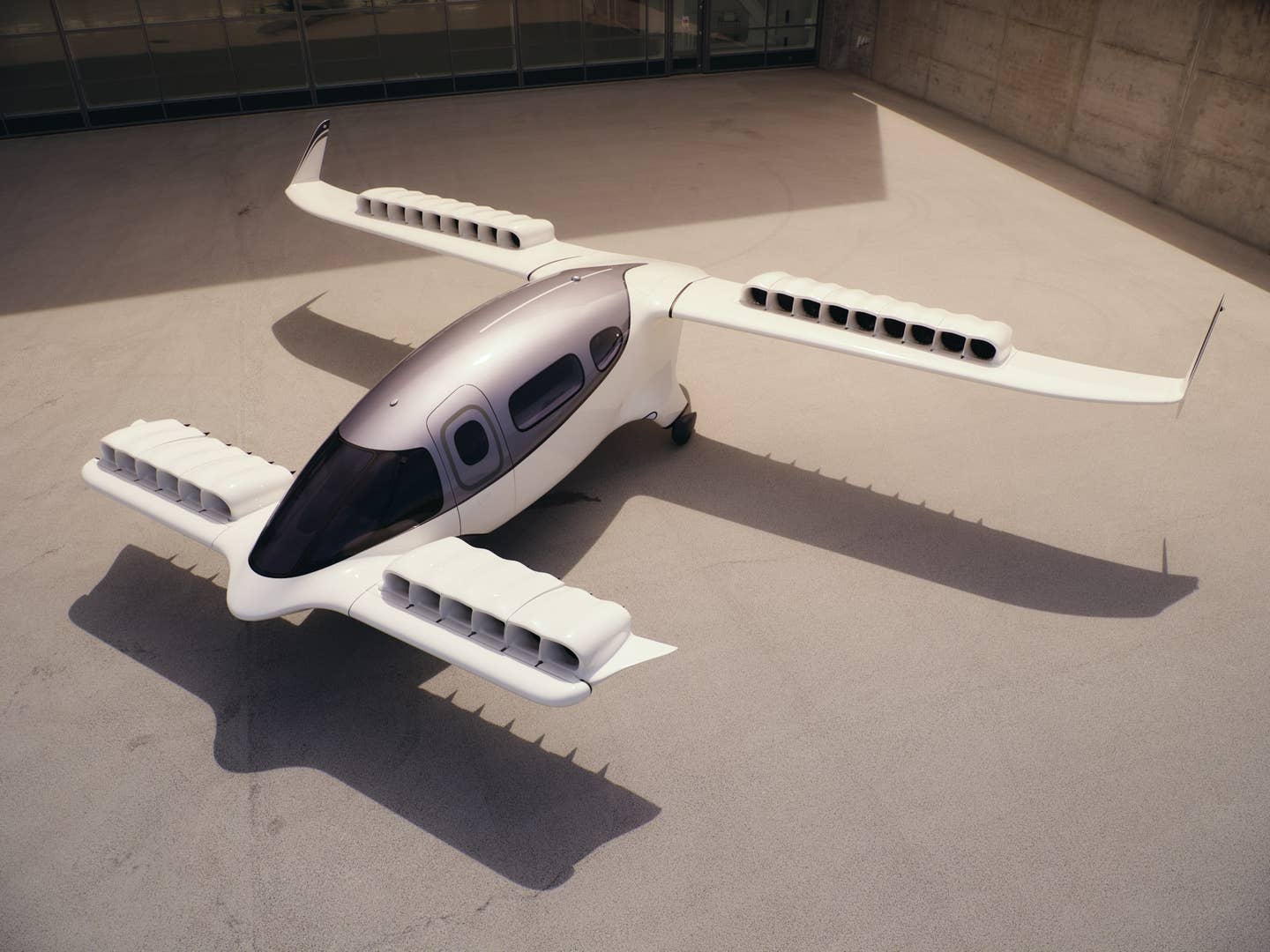

Pipistrel Ramps Up Electric Aircraft Production

Although electric airplanes haven’t gained traction in the U.S., Slovenia-based Pipistrel is doing a brisk business selling them to the rest of the world. It has recently increased production from…

Although electric airplanes haven’t gained traction in the U.S., Slovenia-based Pipistrel is doing a brisk business selling them to the rest of the world. It has recently increased production from four to about six airplanes per month and the company’s factory in Italy will soon double its manufacturing space, with most of that given over to electric aircraft.

When AVweb visited the new Gorizia, Italy, plant last May, the company had room to expand, but has since filled that up and then some, according to Pipistrel’s Michael Coates, who directs marketing for the U.S., Australia and New Zealand.

Who’s buying? “The person who is buying is normally a flying school operation or an Elon Musk-type high net worth individual taken by wanting to save the planet and wanting an electric aircraft,” Coates told us in an interview last week. “There are a few people out there who want something to fly so they feel they’re not damaging the environment,” he adds.

Concerns about noise remain a big driver, Coates says. “In Europe, it’s the noise. Electric airplanes are a lot quieter. In countries like Switzerland, they have extremely strict noise regulation and that’s driving the change to electric,” he says.

Currently, Pipistrel sells the Alpha Electro, which is essentially an electrified version of its Rotax-powered Alpha trainer. Pipistrel has long recognized that electric airplanes are hobbled by their short endurance and has encouraged buyers to purchase both the gasoline and electric versions. The Alpha Electro is suitable for pattern and practice area work while the gasoline model can be used for cross-country training.

The next version of the Electro will be certified under EASA CS LSA and will include water-cooled batteries. Coates says this may provide two improvements: faster charging time and longer battery life due to better thermal stability.

“The problem with rapid charging is to control the temperatures. With an air-cooled system, you can reduce the temperatures by about 10 degrees Celsius. With water cooling, you can drop it down by 20 degrees,” Coates says. Although Pipistrel hasn’t confirmed this by field experience yet, water cooling could reduce charging times well below the one minute of charge for one minute of flight that’s now the rule of thumb. The cooling system has a Rotax-type oil cooler radiator with a small electric pump to circulate standard engine coolant.