Continental Calls for O-360, O-470, O-520 and O-550 Engine Counterweight Inspection (Corrected.)

Continental Aerospace Friday said it’s asking owners of O-360, O-470, O-520 and O-550 series engines manufactured after June 1, 2021, and with fewer than 200 hours to perform crankshaft inspections…

Continental Aerospace Friday said it’s asking owners of O-360, O-470, O-520 and O-550 series engines manufactured after June 1, 2021, and with fewer than 200 hours to perform crankshaft inspections to check counterweight retaining ring installations. The announcement from Continental follows a report from Cirrus on Wednesday that it has grounded all of its own aircraft in response to an alert from Continental about a potential engine manufacturing defect.

Here's the full statement from Continental: “Continental has identified a potential safety of flight issue for aircraft equipped with Continental 360, 470, 520, 550 series engines and replacement crankshaft assemblies. Consequently, Continental is preemptively advising that an inspection should be performed to confirm that the crankshaft counterweight retaining ring was properly installed in new and rebuilt engines assembled between June 1, 2021, and February 7, 2023.

“This advice also applies to replacement crankshaft assemblies manufactured between June 1, 2021, through February 7, 2023. Continental proactively recommends that all flights powered by the aforementioned engines with less than 200 operating hours be limited to 5 additional flight hours with the essential crew to position the aircraft at a maintenance facility. To further clarify, Continental engines with over 200 hours may continue normal flight operations. A service bulletin with affected serial numbers will be forthcoming.”

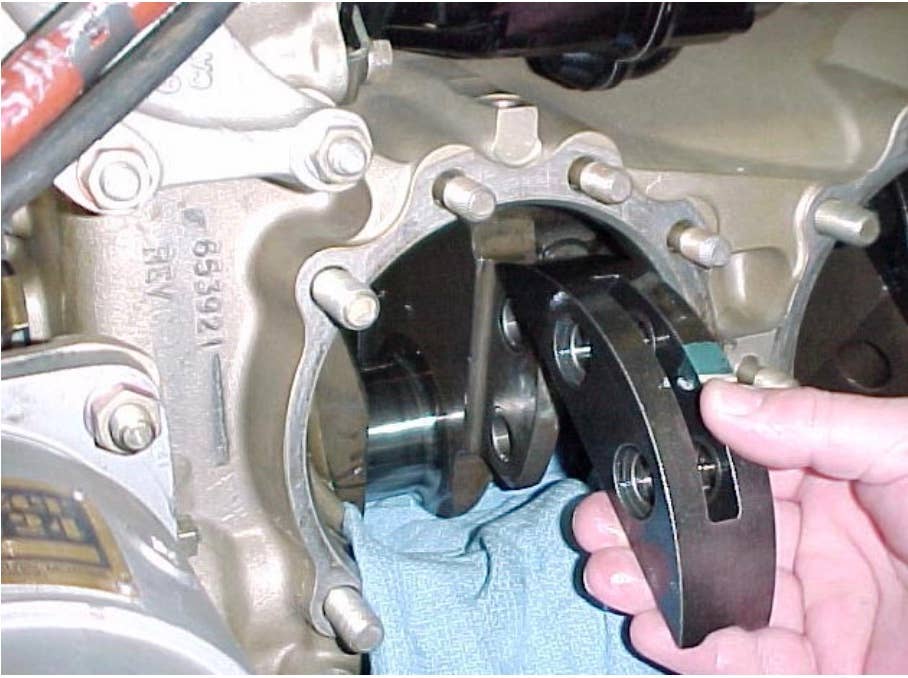

The total number of engines affected is about 2000, but Continental said it's unknown how many of those are beyond 200 hours. Warranty performance and reimbursement is described in this service bulletin released on February 13. On many of its engines, Continental uses moving counterweights to reduce torsional loads on the crankshaft. The weights are held in place on the crankshaft with a pin arrangement secured with snap rings. The weights counteract torsional loads by sliding across a small range of movement. The defect, says Continental, is due to an assembly error, not an incorrectly manufactured part. As described in the service bulletin, the weights and snap rings can be accessed by removing cylinders without the need to split the engine case or remove the engine from the airframe. The photo in this story depicts a counterweight removed, but this service instruction only requires checking the snap ring, not removing the weights. All of the engines in question are six-cylinder models.