Diamond Factory Maintenance Mis-Rigged DA42 Rudder

Canada’s Transportation Safety Board says Diamond Aircraft’s factory maintenance staff mis-rigged the rudder cables on a DA42NG, contributing to an accident that heavily damaged the twin. In its final report…

Canada's Transportation Safety Board says Diamond Aircraft's factory maintenance staff mis-rigged the rudder cables on a DA42NG, contributing to an accident that heavily damaged the twin. In its final report the TSB said the plane, registered to the company's U.S. sales division, was on its post-maintenance test flight on May 25, 2022, when it yawed left on takeoff and the pilot was unable to properly control it. The aircraft landed heavily on the grass at London Airport, where Diamond Aircraft has its North American headquarters, and was badly damaged. The pilot suffered minor injuries. Diamond did not immediately respond to an after-hours email request for comment, but we will publish its response if it is forthcoming.

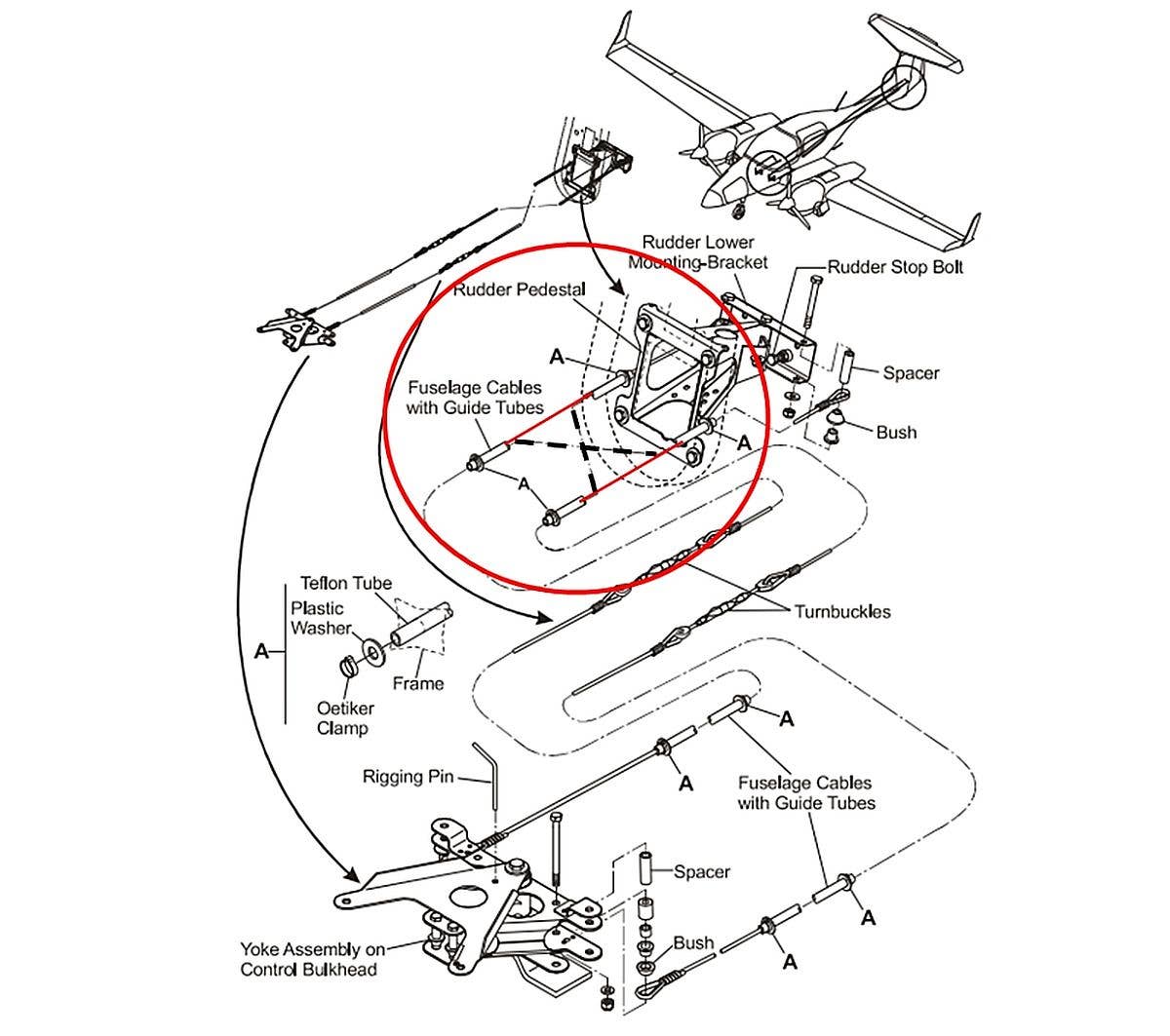

Examination of the aircraft revealed that rudder cables had been installed incorrectly after some worn control cable guide tubes were replaced during heavy maintenance of the aircraft. The plane was undergoing a 2,000-hour inspection and overhaul, which involves partial disassembly of the airframe, replacement of the engines and general refurbishment of the aircraft.

The TSB report said the worn tubes were discovered by an apprentice mechanic who was then tasked with replacing them. When he put the system back together again, he set up the cables incorrectly and that resulted in the rudder moving in the opposite direction to control movements. "This was the first time the apprentice changed the rudder cable guide tubes on a DA 42 and he was not aware that they had to cross over each other," the report said. "The apprentice’s previous experience with rudder controls at Diamond Aircraft Industries Inc. was on a DA 20 aircraft. The rudder cables on that aircraft run parallel to each other."

The TSB said the guide tube snag was not properly documented and the mechanics who oversaw the apprentice did not give him guidance in the correct configuration of the control cables. "The team lead did not provide the apprentice with any reference material, such as the manufacturer’s installation drawings," the report says. "The team lead also did not ensure that the apprentice knew and understood that the rudder cable guide tubes crossed over each other in the rear fuselage, as described in the AMM."

The TSB said the pilot did a thorough preflight inspection but it's difficult for the pilot to see the rudder when checking control movement and he did not notice that the rudder moved opposite to control inputs.