Accident Probe: Carb Ice In Cruise

When one pores over the number of accident reports I have over the years, a few things stand out. One is there are a lot of engine failures resulting in…

When one pores over the number of accident reports I have over the years, a few things stand out. One is there are a lot of engine failures resulting in the NTSB’s definition of an accident. Another is that post-accident investigation frequently fails to identify a reason for the failure; the engine runs fine when tested later. And we have to remember that many engine failures are not reported when there’s no substantial damage or serious injury.

In other words, the reasons for many engine failures can be hard to nail down, and there are far more of them than make the NTSB database—pilots often either resolve the problem while airborne or get back on the ground without damage or injury.

The lack of a reason for an engine failure can be vexing. An obvious cause is fuel mismanagement; there’s fuel aboard but it’s not getting to the engine for some reason, usually pilot error. But what if the failure has little to do with the pilot and more to do with something that leaves no evidence behind? Something like carburetor ice?

Of course, the phenomenon is something only affecting carbureted engines; those with fuel-injected engines are immune, but remain susceptible to other induction-related icing issues. So one relatively easy way to avoid carb ice is to fly fuel-injected engines.

Regardless, I’ve long been convinced a lot of reported engine failures have carburetor ice as a root cause, the evidence of which melts away before it can be verified. Although instrumentation exists to at least alert pilots to the phenomenon, it’s rare to have field data identifying carburetor ice as the culprit, at least as the cause of a crash. Here’s an example of an accident, though, in which carb ice was definitively identified as an initiating event.

Background

On November 11, 2020, at 1144 Pacific time, a 1973 Cessna 177B Cardinal was substantially damaged when it stalled and spun as its pilots attempted an engine-out emergency landing at Whidbey Air Park (W10), in Langley, Wash. The private pilot (male, 78) and flight instructor (male, 25) were fatally injured. Visual conditions prevailed.

The airplane departed at about 1110 and climbed to 6500 feet MSL, where it cruised for about 16 minutes before groundspeed decreased and a descent began. The flight instructor reported to ATC that they were declaring an engine-related emergency, and the airplane’s transponder code changed to 7700. He added that the airplane was “unable to maintain altitude.”

After some initial indecision on a divert field, the airplane flew toward W10. The last communication from the airplane was the flight instructor reporting the airport in sight as its track turned toward it. The last radar point was over the runway at an altitude of about 300 feet.

Investigation

The airplane came to rest nose-low, at the base of a tree. Both wings remained attached to the fuselage, with a tree-shaped indentation along the top of the right wing. Both fuel tanks were breached. The empennage remained intact but exhibited impact-related damage.

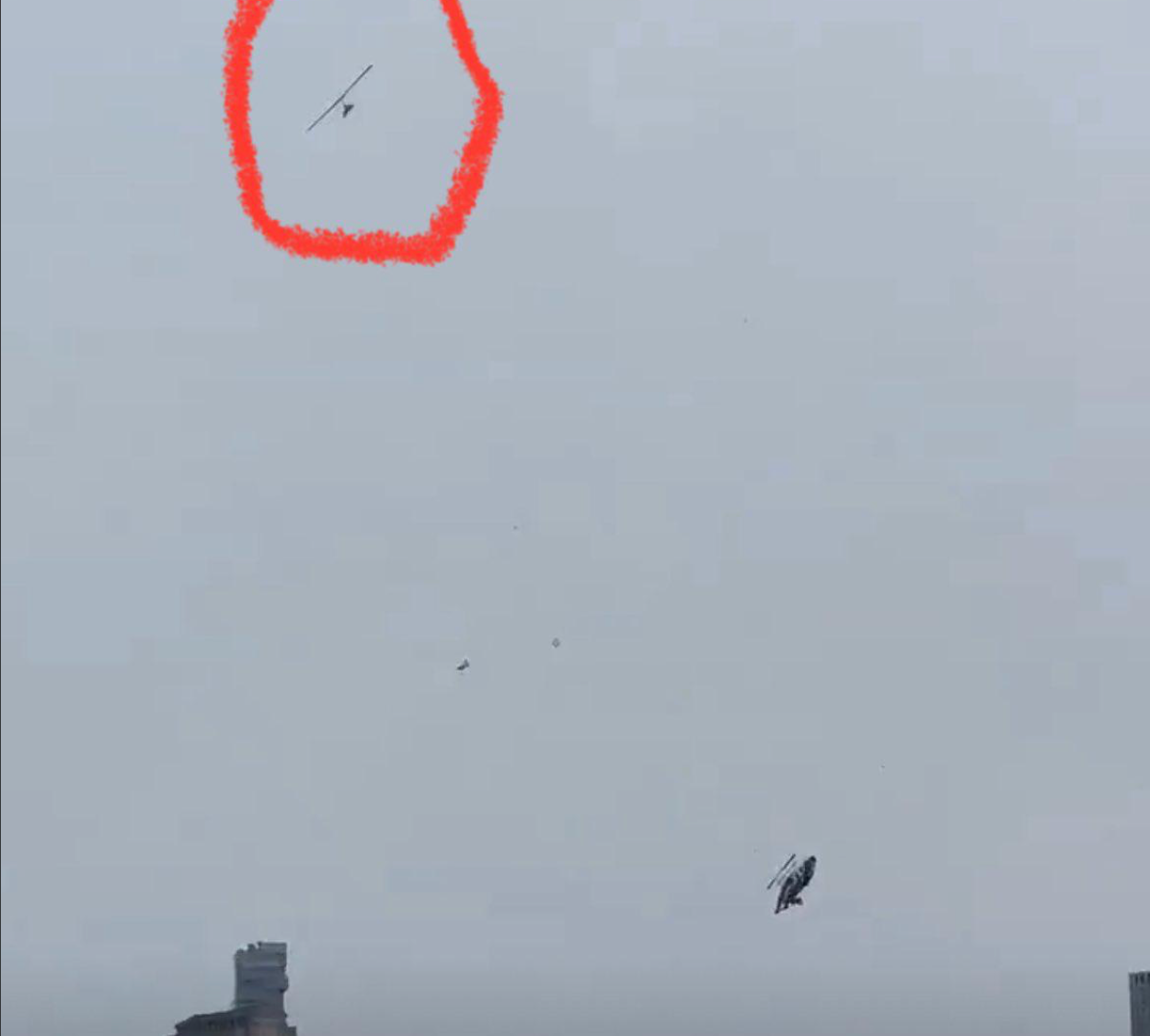

A witness observed the accident airplane at about pattern altitude passing from west to east. It appeared the airplane was “porpoising,” that the propeller was not turning and there were no audible engine sounds. As the airplane passed over the runway, the left wing dropped, and the airplane spun out of sight behind the trees and hangars, impacting terrain.

Flight control continuity was established throughout the airframe. The fuel strainer bowl exhibited some minor debris. The rest of the fuel system and its components was clear of debris or blockages. Both the engine induction and exhaust systems sustained crush damage, consistent with impact.

There were no visual indications of catastrophic engine failure. The engine remained attached to the firewall. Other than severely worn spark plugs, the engine exhibited no anomalies preventing normal operation: The crankshaft was rotated using a hand tool, with compression noted on all cylinders. The single-drive dual magneto made spark on all eight ignition leads. Although the carburetor was impact-damaged, it displayed no sign of failure, was clear of debris and remained secure to the throttle arm, which moved freely from stop to stop.

The airplane’s engine monitoring system recorded data showing carburetor temperature steadily decreasing from 31 degrees F during the accident flight. When it reached 17 degrees, there was an abrupt decrease in fuel flow and a corresponding reduction in exhaust gas temperatures. For the remainder of the flight, exhaust and cylinder head temperatures slowly decreased as the carburetor temperature slowly increased.

The nearest weather reporting station, about nine nautical miles southeast of the accident site, reported temperature as six degrees C with a two-degree C dewpoint. The FAA’s carburetor ice chart advises this temperature/dewpoint spread is consistent with serious icing at cruise power.

Probable Cause

The NTSB determined the probable cause(s) of this accident to include: “The flight instructor’s failure to maintain airspeed, which resulted in an aerodynamic stall and subsequent loss of control while attempting to conduct an emergency landing. Contributing to the accident was a total loss of engine power as a result of carburetor icing.”

Tracking data show the airplane momentarily turning away from W10 before turning back toward it, still descending. Without that slight deviation, they might have arrived over the airport with enough energy to make a runway.

When ATC asked if carburetor heat had been applied, the flight instructor replied “affirmative.” We don’t know when it was applied, or if it was fully applied, though, but it’s likely it was one of the first responses to the power loss. It might have been too late by then.

Many pilots have been trained that carburetor heat is only necessary at reduced power settings, and it became ritual to apply it as power was reduced for landing. Meanwhile, some airframe/engine combinations are more susceptible than others.

We don’t know the power setting used for the normally aspirated engine on the accident flight, but the airplane was equipped with sensors and instrumentation the pilots could have used to identify they were at greater risk of carburetor icing than they presumed.

Preventing Carburetor Ice

The FAA’s Pilot’s Handbook of Aeronautical Knowledge (FAA-H-8023-25B) includes a comprehensive discussion of the need and application of carburetor heat. Its guidance includes the following tips:

- Carb heat can melt ice if the accumulation is not too great. Using it as a preventative measure is the better option.

- If ice is present, applying partial heat or leaving heat on for an insufficient time might aggravate the situation.

- Carb ice is most likely to form in the temperature and humidity ranges depicted in the chart above, but is possible under other conditions.

- If carb icing conditions are suspected and closed-throttle operation anticipated, fully apply carburetor heat before closing the throttle and leave it on during the closed-throttle operation.

- Carburetor heat reduces engine power because the heated air is less dense than the outside air, enrichening the mixture.

- If ice has formed, full carb heat will further reduce power and may cause extended engine roughness. Carb heat must remain in the full-hot position until normal power returns.

Aircraft Profile: 1973 Cessna 177B Cardinal

OEM Engine: Lycoming O-360-A1F6

Empty Weight: 1643 lbs.

Maximum Gross Takeoff Weight: 2500 lbs.

Typical Cruise Speed: 123 KTAS

Standard Fuel Capacity: 50 gal.

Service Ceiling: 14,600 feet

Range: 490 NM

VS0: 46 KCAS

This article originally appeared in the November 2022 issue of Aviation Safety magazine.

For more great content like this, subscribe to Aviation Safety!