One Piece At A Time

“Ever since I was a kid, I’ve always liked to make things, and I thought an airplane would be the ultimate project,” said Les Krumel of Moriarty, New Mexico, a…

“Ever since I was a kid, I’ve always liked to make things, and I thought an airplane would be the ultimate project,” said Les Krumel of Moriarty, New Mexico, a mechanical engineer who recently retired as a civilian employee of the U.S. Air Force who worked on aerospace projects. That understatement defines his humble personality. Making almost every part, Krumel invested 22 years in his project, and he was not yet a pilot when he started in 1993.

Born and raised in Nebraska, Krumel’s father, Ermin, was a machinist and a tool and die maker. “He grew up on a farm, and there is very little a farmer cannot fix, and I attribute most of my shop skills to my dad,” he said. “He passed away about three years ago.” Krumel cannot pinpoint his aviation inspiration. Growing up, he didn’t know anyone who was into it, but still the allure of flying coexisted with his joy of building things.

After earning his degree at the University of Nebraska in Lincoln, “I was working at the University of Nebraska-Omaha as a technician, kind of a machinist, and a fella asked me to make a couple of parts for him. He explained that he was building a T-18. That’s when I first found out you could build airplanes. I couldn’t afford to buy a plane, but like the Johnny Cash song says, I could build it one piece at a time.”

To determine what airplane to build, Krumel compiled a list from KITPLANES® issues, August 1990, October 1991, July 1992 and April 1993. The list included the Kitfox, Glasair, RANS, RV-3, Pazmany, and Falco. To winnow the list, he compared his accumulated skills to the airplanes’ predominant building materials. Ultimately, “My desire was to find an all-metal, two-seat, low-wing design with a proven heritage and Lycoming engine that offered plans.”

The Thorp T-18 was on the short list; it made the final cut when a friend of his mother, LaVonne, was surrendering his Thorp project and offered everything to him. Bob Kemp has since died, Krumel said, and he does not know why he gave up the project or why he never really started it after buying the plans and materials. After the transfer, the two traveled to EAA Oshkosh 1993. “Boy! That was a thrill!” Krumel said. “As soon as I got home, I got started.”

There are several iterations of the Thorp (see sidebar), Krumel explained, and the plans were for the T-18C, the standard side-by-side fuselage with Luther “Lu” Sunderland’s convertible or folding wing. The Thorp ticked all of Krumel’s design desires, “and the folding wings were a plus.”

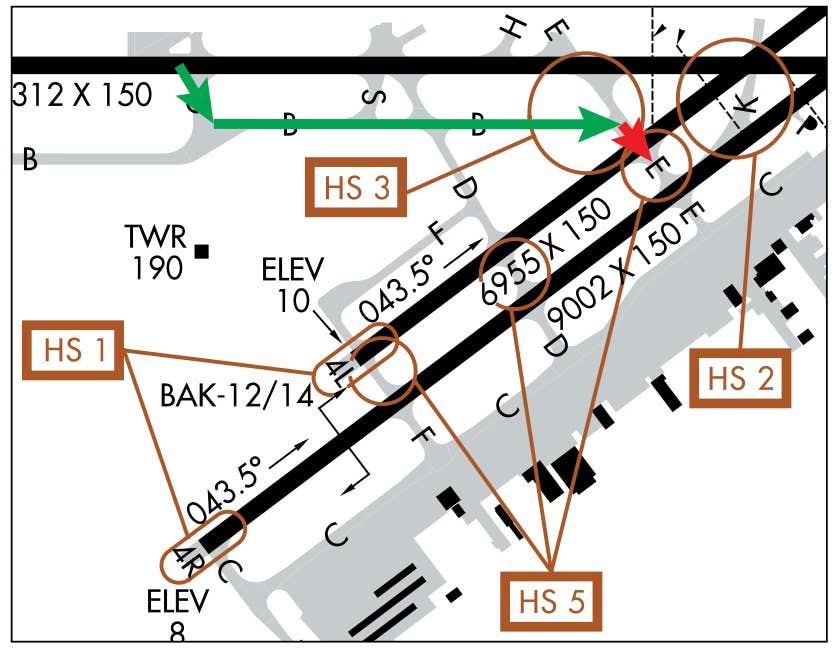

Originally, Krumel planned to keep the airplane in the three-car garage where it was largely created, and he designed and built a steel trailer specifically for the commute. “But it is pretty handy keeping it in the hangar at the [Moriarty Municipal Airport (0E0)]. I fold the wings to do inspections, but that’s about it.”

Under Construction

With all the skills he’d learned so far, “I didn’t know how airplanes were built, so I had to learn a lot of that by reading.” He made special note of the books by Tony Bingelis, The Sportplane Builder: Aircraft Construction Methods, Sportplane Construction Techniques: A Builder’s Handbook, Firewall Forward: Engine Installation Methods, and Tony Bingelis on Engines.

Thorp-specific knowledge came from the community of Thorp builders and the airplane’s plans. “The plans are really good; they explain 99% of everything,” Krumel said. He described them as a “production-quality set of drawings with decimal system precision, butt lines, water lines and stations.”

While studying the plans, Krumel assembled the rest of the necessary materials and made sure his shop was ready, building himself a sheet metal bending brake and rollers to fabricate stringers of the frames. “The project took a little bit of time, 22 years, but I never quit. I was always thinking about it.”

Nine years after starting the Thorp, Krumel and his wife, Linda, started drawing plans for the house that consumed some of his building time. They moved into the 2400-square-foot, two-story home in 2005. Its three-car garage was his airplane shop.

Working on one component at a time, Krumel made all of the parts and then assembled them. He built the fuselage first because it “gives you something motivational to show.” Then he added the landing gear, tail feathers and wings. “I didn’t have a lot of help. My wife helped on occasion, and my son, Caleb, helped me with the wings—there are places that are hard to reach—but [in most cases] I found ways to do things myself,” Krumel said.

“Before the internet builders’ forum we used to have a newsletter, and that’s where a lot of creativity would show up. That’s where I got plans from John Walton for the wet-wing bays that increased the fuel capacity another 24 gallons.” After following the plans, with the 29-gallon header tank in front of the cockpit, Krumel didn’t “see the need to fly any leg for more than 3 hours, so I never connected the plumbing that would add 12 gallons per side, but it’s available.”

The fuselage tank is aluminum. “I made all the pieces and a friend welded it. My dad taught me to weld as a kid, gas, MIG, and stick,” but steel is his medium. His shop is also home to a drill press, mill and lathe, on which he turned the axles for the Thorp’s trailer, countless bushings, the copilot’s brake master cylinders, the tail position light and the stepped conical trim button on the pilot’s joystick.

He cut the grips from blocks of nylon and refined them with files and sandpaper. Microswitches control the push-to-talk circuit, the flaps and the trim. Krumel also electrified the manual flaps and pitch trim, and added roll trim. He designed and built a motor mechanism for the flaps. Microswitches illuminate panel lights that indicate the flaps’ position, “most importantly, all the way up.”

Similar lights report on his pitch and roll trim system. Buying small electric motors, he created his own servos. “The plans have a jackscrew trim on them, and I put a motor on it. Some of these ideas came from the online builders’ group, but I pretty much came up with my own designs.”

The only parts he did not make were the canopy, spinner and some fiberglass parts. “I did learn to work with fiberglass to make a few mods. I read up on it and got some tips from other people.” He made cowl bump-outs for the carburetor, tips for the tail feathers and strobe lights on the wingtips.

“Otherwise just about everything was homebuilt, including the audio panel and a flux-gate magnetometer. Although I do really well working with metal, it was a new experience learning to buck solid rivets and to sew upholstery,” Krumel said, adding that his wife provided some guidance on the last task, not to mention her sewing machine.

“The plans are mostly for the airframe, and they don’t talk about some things. The wiring, instruments, whether you add electric trim, that’s up to you. When it comes to things like the engine, firewall forward, you have to make up [the rest of it] yourself with help from other people.

“I enjoyed the wiring. That was a lot of fun.” The panel is home to steam gauges, “but I have an iPad with ForeFlight, an Icom transceiver, Narco transponder and an audio panel (I found the plans on the internet). I don’t have ADS-B Out; out West here, I’m usually flying in Class G [airspace]. I do I have an ADS-B In receiver that shows up on ForeFlight, and the weather radar is really nice.”

The plans show the A-frame landing gear and engine mount, an integrated welded component that supports and directly couples the major loads. “It is simple to fabricate at home, and it is maintenance free and rugged. Its inherent safety feature is that it prevents the engine from penetrating the cockpit in the event of an accident, and the main landing gear legs fold back like sled runners, providing a safety shield,” Krumel said.

“I bought the engine used from a friend, pulled the heads, inspected it, honed it, got new rings and put it all back together.” He finished the 150-hp Lycoming O-320-E3B with a 68-75 Aymar-DeMuth prop.

Krumel built cooling baffles based on a set of RV plans. Working with cardboard templates, he designed and built his own airbox. To improve the thermal efficiency of the heat muff, he arranged coils of copper-coated steel wire in it. “I just figured you needed something in the muff to stir up the air to improve the heat transfer,” he said.

“The part I hated most was painting. It came out good, but it was just unpleasant, all the prep work and chemicals.” Krumel finished his Thorp with two-part automotive polyurethane. “Coming up with the different paint schemes was the fun part.” Inspired by a magazine photo of the prototype F-16, he worked with red, white and black. “I liked that scheme and it was also a tribute to my dad. He always liked those colors.

A member of EAA chapter 1306, Krumel said its technical counselor examined his project several times, and designated airworthiness representative Ron Livingstone inspected the Thorp on behalf of the FAA.

Flying

Chuckling at the memory, Krumel said he was halfway through the Thorp’s 22-year build, and “I thought I’d better learn how to fly.” A civilian employee at the Air Force base, he joined the aero club and earned his private pilot certificate in a Cessna T-41 in 2002.

When Krumel finished his Thorp in 2015, James Grahn made the first flight in November 2015. “He’s a friend, a great help and real champion promoting the Thorp and safe flying,” Krumel said. It “went off without a hitch—no adjustments were necessary. He went up to 11,000 feet, did some slow turns, some imminent stalls. The trim was perfect.”

A former Air Force fighter pilot of 21 years service, Grahn is a CFI/MEI who has logged more than 1000 hours in his T-18, the Patriotic Princess. He launched Thorp Central in 2013 when he began acquiring the assets of Classic Sport Aircraft when its founders retired after supporting the design for nearly two decades. Thorp Central offers plans, component kits and complete kits for the Thorp S-18.

“Needless to say, my own first flight, and all the others, is still a thrill,” Krumel said. Working through the set of test cards he created for his Phase I flights, he limited each one to 30 minutes. There were no surprises, but each flight was exciting. “A low-time pilot with just transition training, I was just learning about the airplane and getting used to flying by myself,” Krumel said.

“When I finished the Thorp in 2015, Jim [Grahn] gave me some transition training. A local fella, a CFI and member of the EAA chapter, gave me 10 hours of tailwheel training in an Interstate Cadet; it lands at about 35 mph, a real easy plane to fly. I do wheel landings in the Thorp at 75–80 mph.”

With Phase I flights complete, his wife, Linda, was his first passenger. So far, Krumel has logged more than 220 hours in N48LK, for his initials and his goal of flying to all 48 contiguous states.

His first journey was to his birthplace, Nebraska. This cross-country was the realization of a “dream I had, to fly home to Omaha, to have a family reunion, to show the plane to my mom and everybody, and to have a champagne toast.” Since then, he’s flown for a visit with his daughter in Florida and his son in Iowa. He’s also landed in Arizona, Texas, Minnesota and Oshkosh, Wisconsin, where EAA judges presented him with a plans-built outstanding workmanship award.

Photos: Les Krumel.

Thorp Timeline

A graduate of the Boeing School of Aeronautics in Oakland, California, John W. Thorp (1912-1992) worked for most of the major airframe manufacturers and did the preliminary design of the Lockheed P2V Neptune, a twin-engine land-based Navy patrol plane. After WW-II he designed three versions of the Thorp Sky Scooter, the forerunner of the Piper Cherokee. He also put a nosewheel on the Beech 18 and designed the Wing Derringer, a two-seat twin.

Thorp introduced the T-18 Tiger, his 18th design, at EAA Rockford in 1963. In an era of tube-and-rag homebuilt airplanes, it was one of the few simple-to-build, all-metal designs. The outboard dihedral makes for a 90° joint with the fuselage, reducing drag and eliminating the need for a fillet or fairing.

Thorp held the patent for the all-flying horizontal tail (as used on the F-86 and subsequent go-fast airplanes), so he employed it on the T-18, which saved weight and simplified construction. A 125-hp Lycoming O-290-G ground power unit, then readily available, powered the original, which had an open cockpit and partial cowling with the cylinders in the breeze.

Thorp originally planned to sell parts with the holes marked and ready to drill for assembly. That didn’t happen, but the airplane was easily scratch built thanks to the quality of its plans. To help builders, Dick Cavin and Luther “Lu” Sunderland started the T-18 Mutual Aid Society and newsletter than ran for 25 years.

The newsletter reported more than 140 T-18s were flying in 1975, the year Lu Sunderland created the folding-wing T-18C, which combined Sunderland’s convertible wing with the original T-18 fuselage. The folding wings were a supplement to the original plans, and Thorp sold them until 1984, when he retired.

Seeking a bit more width, Sunderland expanded the original T-18 fuselage to create the T-18W, which was 5 inches longer and 2 inches wider at the cockpit. Like his folding wings, these supplemental plans were available through Thorp until he retired.

The T-18CW combined Sunderland’s folding wing and wider fuselage, and the availability of these plans retired with Thorp. This was the predecessor of the S-18, Sunderland’s 1974 redesign of the T-18, which issued a completely new set of drawings. They incorporated a new airfoil, the LDS-2, which is similar to the GAW-2 airfoil. The new wing, standing on 2-inch longer main gear legs, had more flap area, which reduced the touchdown speed by 10 mph.

Plans and kits are available from Thorp Central, which was born of the assets from Classic Sport Aircraft, nurtured for 17 years by Mike and Frankie Archer. Jim and MaryKay Grahn began their acquisition of these assets in late 2013. It now offers the S-18 as a complete kit ($20,500) and its individual components.

—S.S.

Thorp T-18 N48LK

- Kit price: $20,500

- Estimated completed price: N/A

- Estimated build time: 22 years

- Number flying (at press time): 400 (U.S.)

- Powerplant: Lycoming O-320-B3B

- Propeller: Aymar-DeMuth 68-75

- Powerplant options: O-290, O-320, O-360

AIRFRAME

- Wingspan: 20 ft 10 in

- Wing loading: 18.6 lb/sq ft

- Fuel capacity: 29 gal

- Maximum gross weight: 1550 lb

- Typical empty weight: 950 lb

- Typical useful load: 600 lb

- Full-fuel payload: 425 lb

- Seating capacity: 2

- Cabin width: 38 in

- Baggage capacity: 85 lb

PERFORMANCE

- Cruise speed: 180 mph

- Maximum rate of climb: 1500 fpm

- Stall speed (landing configuration): 58 mph

- Stall speed (clean): 65 mph

- Takeoff distance: 1000 ft

- Landing distance: 1800 ft

Specifications and pricing provided by the builder.

A pilot since 1976, Scott Spangler was the founding editor of Flight Training magazine. In 1999 he launched and edited NAFI Mentor for the National Association of Flight Instructors, and for seven years was editor in chief of EAA publications. As a freelancer he’s written for Air & Space Smithsonian, Overhaul & Maintenance, Aviation for Women, Twin & Turbine and a number of non-aviation titles.

For more great content like this, subscribe to KITPLANES!