GAMI Says All High Aromatic Gasolines Are Hard On Paint

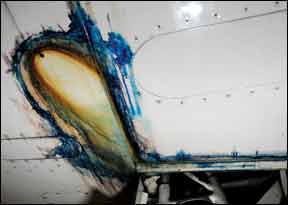

An Aviation Consumer article in 2012 used this (low resolution) photo to show the damage caused by leaking 100LL.

Aviation Consumer

General Aviation Modifications Inc. says long-term exposure of painted aircraft surfaces to avgas with high aromatic content, like its G100UL and, potentially, 100LL is "not recommended" but "incidental contact should not cause paint to peel." The company was responding to a video released by a California A&P who conducted his own set of material compatibility tests on the high-octane unleaded fuel. Michael Luvara found that when G100UL was allowed to evaporate on a painted surface, the residual liquid left after the most volatile constituents would, over time, cause paint damage. He also found that nitrile O-rings swelled when submerged in the fuel for five days.

In its reply to Luvara's snag report to the GAMI website, the company said wiping ups spills will prevent most issues. He also said wax and ceramic sprays will help prevent the yellowish staining that can occur if the fuel is left on the paint. As for the O-rings, GAMI said it knew that the fuel would swell old-style nitrile and Buna-N rubber seal components, but its testing also showed the materials weren't damaged and retained their sealing ability. The full GAMI response is copied below.

Meanwhile, GAMI founder George Braly said fuel leaks have plagued aviation since long before G100UL was created and cited a 2012 report in Aviation Consumer magazine dealing with the various causes and effects. "Fuel leaks are hard on aircraft painted surfaces, be those 100LL or G100UL Avgas," Braly told AVweb. "This issue that Michael describes is nothing 'new' and is not in any way 'unique' to G100UL Avgas."

GAMI Full Response to Material Testing Video

"Mr. Luvara,

Thank you for your submission. It’s important to us that we receive timely news of potential issues and concerns from the field.

While It is not recommended that painted parts are soaked in high aromatic content fuels (including G100UL), incidental contact should not cause paint to peel, except maybe in cases of poor surface prep. However, staining can occur if it isn’t promptly cleaned up. A surface treatment such as a heavy wax or “ceramic” spray on coating with help greatly with that.

Nitrile and Buna-N rubber compounds aren’t the best for long term exposure to fuel. Modern aircraft have long replaced those components with fluoroelastomers (such as Viton®). However, our testing has shown that even though the older rubber compounds may swell in high aromatic fuel formulations, they don’t deteriorate. This swelling has no negative impact on their ability to seal, and in some cases actually improves the mechanical sealing action of older rubber seals.

It’s important to note that high aromatic content is also allowed in 100LL, and can be found at certain times of the year in batches from certain refineries. The results of your tests with those particular blends would have likely been similar to what you observed."