Cessna 182 Pre-Buy Check

The venerable C-182 is a legend in its own time with an array of models, including some with mogas capabilities.

The Cessna 182 series is one of the most popular and prolific all-purpose flying machines in the general aviation fleet. They are dependable, straightforward, and easy to fly. They are traded frequently on the market, and lots of people are looking to buy one at any given time.

While the huge run-up in the cost of gas may dampen enthusiasm, we may find that the older models with low compression engines capable of running on auto fuel grow more in popularity. These engines were built through the 1977 model year. We will orient ourselves primarily to the older models here.

The first factor to consider is the kind of service to which it has been subjected. This will definitely affect maintenance trends that would otherwise alarm you or cause you to miss something important. As an example, aircraft fitted with oversize tires and heavy-duty landing gear may be the ones that spend most of their time on unimproved strips.

On the other hand, the Cessna 182 in pristine condition with low hours will be the one that might need additional maintenance for surface corrosion problems as well as repeated repairs to dried-out hinge points and frozen bearings. The type of maintenance required and the associated costs for repair are a direct reflection of the aircraft's history. If it has been hangared most of its life, that can be a big plus in low corrosion.

The heavy use found in training environments or long periods of inactivity will require more maintenance. Heavy-use aircraft need replacement of things like wheel halves, brake housings, and brake caliper torque plates, to name a few. Things can get worse from there.

Empennage attach points, surface control cables, and primary structure repairs are also areas of concern. For aircraft in long-term, improperly prepared storage, replacing control surface attach point bearings, treating interior skins for surface corrosion, and replacing corroded nose strut bearings is common.

If usage generally has been light but the maintenance has been repeatedly high or frequent and not of a preventive nature, look for some sort of unusual situation or "special" use that would cause the recurring problems. People sometimes only fix the symptoms.

If the tires have been repeatedly replaced, check for a problem with gear alignment and make sure the brake discs and linings are compatible. If pneumatic instruments are constantly being overhauled, check the vacuum system for proper operation and contamination. If symptoms keep popping up, do some detective work for the source.

Engine Points

By far, the most critical and potentially expensive item attached to the Cessna 182 is the engine. It is also the one thing that gets the most attention during a pre-purchase inspection.

When looking through the engine logbook, look for trends in maintenance. Check for things like cylinder changes, frequent valve work, oil cooler or thermal bypass valve changes, or anything else that could give you a clue into the past problems associated with your potential purchase.

Look for premature engine and propeller changes and note the frequency in accessory replacements. Take your time with the logbook. If entries look sparse or hurried, it's a sure bet that something important has been left out.

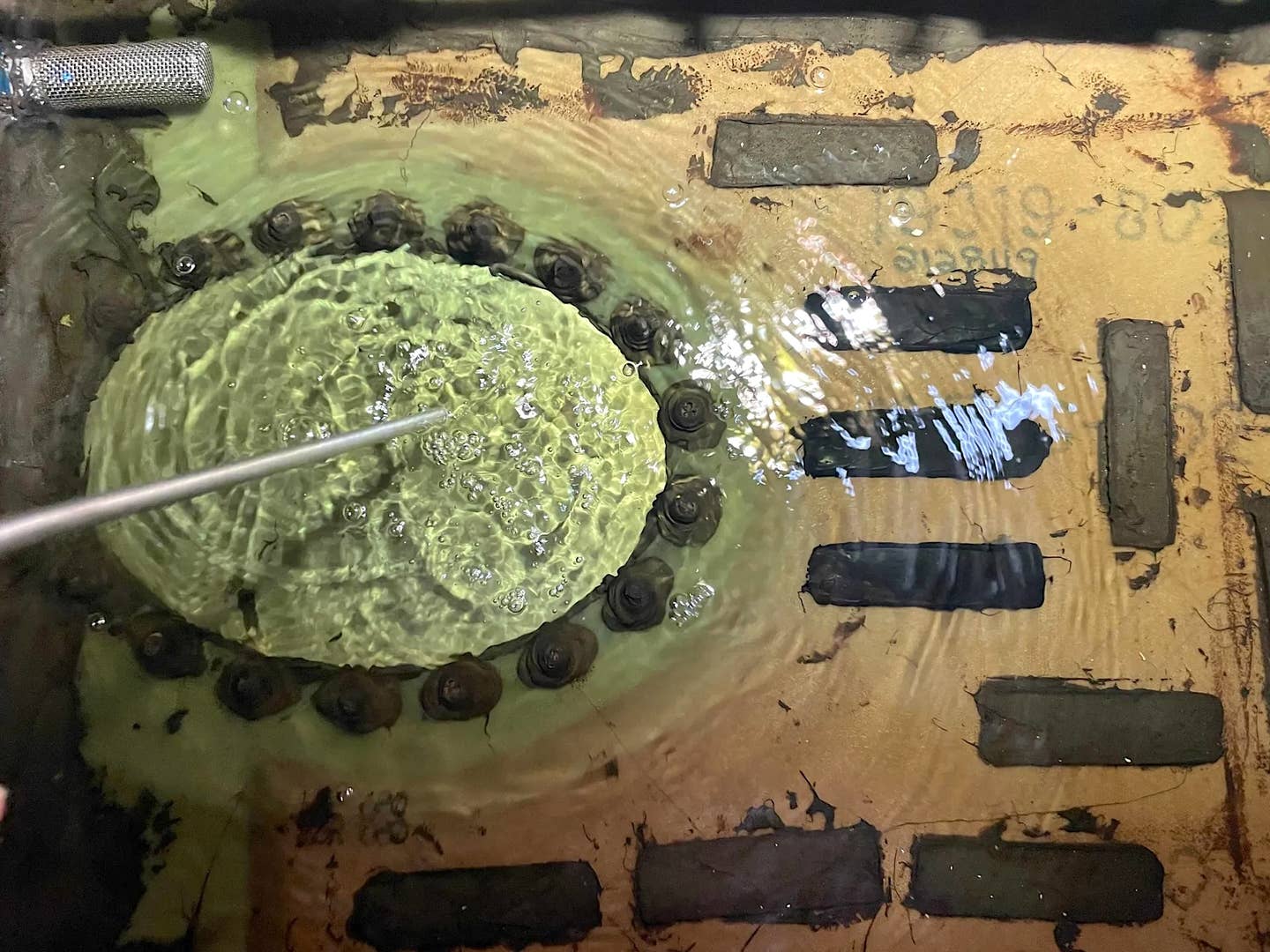

As always, inspection of the standard engine items will be necessary. Perform a cylinder compression check, borescope the cylinders and inspect the oil filter for contamination. Flight check the engine and note oil pressures, oil temperatures, cylinder head temps, and engine power and performance. Check the climb and cruise performance against book specs.

This is also a good time to check the operation of all avionics and autopilot functions. After the flight, check the engine breather tube for any signs of blowing oil and check the belly for evidence of grease and grime accumulations.

It would be wise establish oil consumption before you sign the check. So, check the oil level before and after the flight. Make sure the aircraft is level and has been sitting for a while before pulling the stick. Four to 5 hours a quart is not at all unusual in the O-470.

Compression and TBO

An engine that has been well cared for will have frequent oil and filter changes (every 25 to 35 hours) and 50- or 100-hour inspections (if flown that much between annuals).

The O-470 series is a hearty engine with few, if any, quirks to look out for. Compressions on this engine generally stay above the mid 60s for most of its TBO life. Anything lower should be investigated.

If the magnetos are the Bendix brand, check the status of the latest impulse coupling AD note. New-style couplings use a snap-ring retainer rather than the riveted style. Only specific Lycoming engines are still subject to repetitive inspections by AD 2005-12-06.

Installing a full-flow filter is a plus but investigate the status of AD 96-12-22 issued against the Cessna filter adapter. Repetitive inspections of this adapter are called out unless it is replaced with the Continental equivalent. If the AD hasn't been complied with and the adapter or oil-pump housing requires replacement, plan on spending between $900 and $1800 for the effort. If you do have to replace the adapter or housing, save some hassle and install the TCM adapter. It is not affected by the AD.

The TBO on the O-470 is 1,500 hours. This can be extended to 2,000 hours on the O-470-U model (‘77 and later 182s) if the correct cylinder and piston assemblies are installed. Indication of this change will be called out by stamping a different specification number on the engine data plate.

This specification number is stamped in parentheses after the model designation. Any O-470-U engine that has an extended TBO will be identified with spec. numbers (11), (12), (13), (14), (17), or (18). Refer to Continental #SIL 98-9C for more information.

If you are looking at one of these 2,000- hour engines, be sure to take a close look at the cylinder condition, especially when the cylinders have accrued more than 1,500 hours total time in service. The slow-turning, high-compression -U engine is tough on barrels and compression will begin to sag on mid-to-high time engines.

The standard O-470-L, -R, and -S engines will usually hold higher compressions for a longer period of time due to the lower compression ratios used. As always, abuse and/or harsh operating environments play a role in cylinder life as do multiple runs on welded and reworked cylinders.

Oil Squirts and Oil Pumps

The life of an O-470-R could be extended by the installation of piston-cooling nozzles in the case. These oil-squirters helped to extend cylinder and ring life, keep compressions up, and keep oil consumption down.

If the factory bulletin was accomplished in its entirety, the -R became an -S and will give better life for the money. Generally, the modification is done at the major overhaul or during a prop strike inspection because you have to split the case to accomplish the addition of the piston oil-squirter nozzles.

Look to see if the oil pump assembly is of the old or new type. The old type is most readily recognizable by the square "acorn" that houses the oil-pressure relief spring. The new type has the large spring housing with an adjustable plunger (threaded rod with a jam nut).

The old type was plagued with low oil pressure problems that caused a lot of grief. Sometimes when the oil was hot the pressure would be at the bottom of the green and sometimes drop out of the green altogether. The newer type housing with its larger oil-pressure relief valve does an excellent job of keeping oil pressures well in the green at most any temperature.

If the engine has this newer-style pump housing and still has oil pressure problems, definitely get it checked out and solved before purchase. There could be a very serious problem within the engine. A flight test on a warm day will verify whether or not hot oil temperatures are going to affect system oil pressure. It's such a problem for some that this check should be considered mandatory.

For the TR-182, the few T-182s that exist, and the R-182, Cessna installed the Lycoming 0-540, parallel-valve engine. This engine is as equally robust and dependable as its TCM counterpart, the 470, and some would argue even more so. The compressions on this engine shouldn't go much lower than the high 60s to low 70s.

If you find one lower, a further investigation is usually warranted—especially in the exhaust valve area. Inspection of the turbocharged models won't be much different from the normally-aspirated versions because the engine is "normalized" rather than boosted. However, take a good look at the turbocharger, wastegate, and throttle interconnect plates.

Check for smooth operation of the wastegate cable and be sure the wastegate valve is not warped or deteriorated. There is an exception here for turbocharged 182s consistently flown at high altitudes and high cruise-power settings (70 percent or greater).

The additional heat generated by flight operations at altitude combined with less dense air to cool the cylinders and exhaust systems can cause accelerated wear to barrels, exhaust guides, piston rings, and exhaust system plumbing. TBO on the two versions of the Lyc O-540 engine installed in the Cessna 182 is 2,000 hours.

Airframe and Propeller Points

Note that Cessna has available supplemental Inspection Documents in pdf form that would be very helpful on a pre-buy examination among other maintenance uses. On the propeller end, check to see when the overhaul is due. Most propellers aren't in "sync" with the engine when it comes to overhaul time (the prop isn't at TBO at the same time as the engine). And, be sure the blades haven't been filed to minimums.

Reworked blades can look good but at the same time have no material left for reshaping or even filing out nicks. A call to your local prop shop with the make and model of propeller will get you figures for the minimum dimensions at various spots along the blade. If the blades are thin, but serviceable, it gives you a good bargaining chip when discussing price.

A spot that gives trouble every so often is the spinner and spinner bulkhead or backing plate. They tend to crack if the forward spinner support shims aren't set properly or if the spinner is installed in a binding condition. Cracks will start at the AN-3 bolt holes for the crank flange mount brackets and, generally, travel around the bulkhead from hole to hole.

Some may start a radial path to the outer edge. Whichever the case, this situation can progress rapidly once started and, in severe cases, can allow excessive working of the spinner, ruining it in a short period of time. Spinners aren't cheap either.

Some other interesting airframe items to note have to do with the landing gear. The early 182 (most 1956 models) was nothing more than a C-180 with the tail wheel lopped off and a nose gear bolted to the firewall. The fuselage was still built and stressed for a tail wheel and many of the provisions for the tail wheel steering cables and pulleys were left in the aircraft.

Production aircraft also left the forward landing-gear box installed in the fuselage. This practice was discontinued sometime in late 1956. There is an STC for those desiring a tail wheel to convert those older 1956 models back to the conventional Cessna 180 configuration.

To complete the change, you'd need a different cowling and the landing gear legs would need to be replaced. In addition, you would need to change the brakes, the gear saddles, and, of course, you'd need a tail wheel with the associated cables and pulleys.

The purpose of describing this early gear change is to more clearly define the weak points in the nose gear attachment of the old "tall gear" 182. The heavy-duty nose gear fork with the larger tire helps, but it's still not uncommon to inspect one of these airplanes and find that the nose gear has been popped off in the past, so be sure to inspect the firewall for wrinkles.

Even a hard landing can damage the structure in the area of the nose gear. And with two people up front and a full 40 degrees of flaps, it's all you can do to keep the nose wheel from touching first. Check the "tunnel" just in back of the nose gear for repair or reinforcement.

If done properly, it will be stronger than before (a plus). If the damage was just straightened out, or, worse yet, if the damage was not repaired at all, the area will be weak and will very likely cause problems in the future.

It is also likely that if the nose gear has had one of these collapses, one of the wing tips will have been dinged and the rear spar fitting damaged (for some reason usually the left wing and rear spar fitting).

There are rear spar attach fitting repair kits available from Cessna, but make sure the repair has been done properly. It would also help to fly the aircraft to check angle of incidence rigging (adjusted at the rear main spar attach point). This is best done by practicing slow-flight, and straight-ahead power-off stalls.

Make sure that unusual control deflections aren't required to maintain a level attitude. In bad cases, one wing may stall and unexpectedly drop, putting the aircraft into a stall/spin entry situation. Be prepared for anything.

Wheels, Flaps, and Controls

If the aircraft is equipped with the older McCauley wheels (they look like they have spokes) be sure to have them inspected for hub cracks near the outer rim attach areas in the "spoke" members. It is not uncommon to see cracks in these wheels in the described areas (one reason you don't see many of this type of wheel anymore). Many parts are no longer available, which means you may need to go with a refit to Cleveland.

The Goodyear wheels and brakes are still around, too, but are a high-maintenance item and parts are getting hard to find. It's best to go with the Cleveland or Avpro type of wheel. They are relatively trouble free and easy to maintain.

Another area to look at is the flap track to rear spar attach rivets (mainly on the bottom of the wing) on the older manual flap systems. These systems combined a 40-degree flap travel with a manual pull handle.

These flaps can be quickly lowered to the fully deployed position at high flap speeds causing high loads on the flap track attach points. This is usually indicated by "working" of the flap track rivets on the bottom of the wing. If this condition is spotted—or prior repairs have been made in this area—it would be a good idea to do a very thorough inspection of the flap track to rear spar attach points.

Check the tail tie-down ring and ring attach area. Once in a great while, the ring will have been smacked on landing and damage will be inflicted to the lower portion of the rear bulkhead. Although much more common in aircraft with lighter noses (Cessna 150/152/172), it is still possible on the C-182 if loaded aft.

Damage can also occur if the aircraft has been exposed to abnormally high winds with the tail tied down, or when the tie-down ring is consistently used to pull the aircraft back into the hangar (most "T"-hangar entries are uphill). The replacement bulkheads are made from thicker material and will handle this event better.

Look for cracking at the trailing edge of the control surfaces. All sorts of repairs have been spotted on these things and few are approved and fewer still rebalanced. The corrugated aluminum is a 2024T3 alloy and because it is thin, it's prone to crack propagation.

Look especially at the elevator trailing edge tips. These can get pretty bashed up if the control lock isn't in when the tail is dropped to the ground for nose strut, wheel, or some other "tail dropping" service. A re-skin is the best option for bad or severe control skin damage and can be costly if more than one or two surfaces need the repair.

The labor to prepare and install a patch is only about an hour less than it takes to re-skin the whole surface. And patches look a whole lot worse when you're being ramp checked by the FAA. Scab patches, especially flight controls, at best are a temporary fix, and require proper repair.

Look at the leading edge of the horizontal stabilizer. This is a favorite place to push when dropping the tail (this area is not stressed to handle this kind of abuse) or positioning the aircraft for tie-down. This causes nose rib cracking and buckling. The nose rib rivets may be working or gone altogether, not a safe proposition.

If the top of the leading edge on the horizontal stabilizer is deformed or flat, this is usually the problem. This will require removal of the vertical stabilizer and removal and disassembly of the horizontal stabilizer to repair—costly.

Take a good look at the seat rails. Cessna's repetitive AD 11-10-09 calls for repeated inspection of the seat rails for wear and cracking and continues each year until the rails are replaced. Even after the new rails are installed, the inspecting starts all over again 1,000 hours after the part is replaced. A close look during a pre-buy is warranted. Although the rails may not be at the AD wear limits yet, if they're very close, you will be replacing them shortly.

Windows and Tanks

Check the windows and windshield for cracks and crazing. Look especially close at the area of the defroster outlets. Bad crazing will show up first here due to the heat coming from the defroster air.

Look for distortion from excessive polishing or crack removal. It may not be apparent at first but after a few hours of flight even slight distortion can be annoying and cause eye strain—sort of like wearing your old pair of glasses.

Check for excessive movement between the windshield and forward fuselage frame during the engine start sequence and taxi. While some movement is common, too much can create windshield fretting and cracking at the edges. Also, check for wet or rotting upholstery side panels due to water leakage past the windshield or cabin door seals.

Bladder-type fuel tanks on most Cessna 182 aircraft are problematic, requiring some form of maintenance at least once every 12 years or so. Refer to Cessna bulletins and AD 84-10-01-R1. Wrinkles in the bottom of the rubber tanks trap moisture, requiring the installation of a kit to lower the drain port in the tank.

This compliance generally causes enough stress to an old tank to cause leaking of the bladder and cracking of fuel-supply nipples. Replacement costs can bite, but missing an AD check is probably the most risky behavior of all. Some of these ADs can really bite, so we recommend the services on an experienced IA to help you with the search if you find a bird you are really interested in, even though it's free on the FAA site.

We reviewed recent ADs and noticed an AD affecting the R-182 and TR 182RG, T182T as well as many other Lycoming powered aircraft besides the 182. There are a lot of exceptions and FAA issues on this AD, so if you are considering a mentioned 182, be sure to read the AD, especially the end notes and applicability sections.

The AD number was 2006-20-06 and is now 12-19-01, which affects Lycoming (L) O-360, (L)IO-360, AEIO-360, O-540, IO-540, AEIO-540, (L)TIO-540, IO-580, and IO-720 series reciprocating engines.

This AD is old enough that many engines will have been taken care of, but there could still be some planes still vulnerable to the AD requirements.

Essentially it requires replacement of the crankshaft, which in many cases owners may simply elect to overhaul or replace the engine depending on how much time is on the engine.

The FAA coyly says that is not requiring an overhaul, but only replacement of the crankshaft. This AD requires replacing certain crankshafts and results from reports of 23 confirmed failures of similar crankshafts in Lycoming 360 and 540 series reciprocating engines. Miss this AD and it's a fortune even if you only replace the crank.

The original AD became effective November 3, 2006. The AD requires replacement of identified crankshafts in the AD at the earliest of the next time maintenance requires splitting the crankcase, or the time specified for the next engine overhaul listed in Lycoming Engines, SI No. 1009AV, or 12 years from when the crankshaft entered service.

As we have mentioned in the past on some ADs such as one involving a case or crank and waiting too long, it can be extremely costly to do so. Lycoming had a huge price break, (See MSB 569A) but it expired quite some time ago.

The makers are anxious to get these parts off the market and both engine makers tend to offer substantial short term incentives. That's why it's so important to not put off an AD (and associated Service Bulletin or Instruction) until you have carefully analyzed what a delay may cost you in price breaks. ADs rarely go away and waiting is usually a very risky move, hoping it will go away, and you will save the cost.

An operator may request additional time through a request for an Alternative Means of Compliance using procedures found in 14 CFR 39.19. Note that the AD does not require the engine to be overhauled. It only requires replacing the affected crankshaft, which can be done with other maintenance.

Some may consider that a red herring considering it requires such complete disassembly and an overhaul will increase the value of the airplane. The bottom line is don't miss any ADs.

More Recent ADs

We don't have room for all the ADs in which a Cessna 182 from an older model to a new model has an AD to comply with. You need to get with your mechanic or if familiar with the process yourself, go to the FAA.gov Web site to do a search.

Download the ADs on the model that you are interested in. A thorough AD search is an absolute necessity, since some ADs amount to thousands of dollars worth of changes or repairs. This includes a search of proposed rule making, a separate database to make sure there are no potential traps for you as well as checking for any possible ADs or proposed ADs on expensive accessories such as propellers.

Using an experienced IA for a search may cost a few bucks for his time, but he will have the pro software to make a thorough search a snap. It could save a fortune. Once this is done a hands-on pre-buy by your mechanic (who should be very familiar with the model you have in mind) is essential before any money passes hands.

Even the new diesel 182 versions under an STC have an AD. It is AD 2009-04-05 , on Models 182Q and 182R, and concerns the (SMA) Aircraft Diesel Engine (ADE) Model SR305-230-1 or Model SR305-230 converted to Model SR305-230-1 installed under Supplemental Type Certificate (STC) SA03302AT.

This proposed AD would require you to remove the intercooler and the intercooler inlet and outlet hoses, install a reworked intercooler and new intercooler inlet and outlet hoses, inspect hoses and clamp torques, and repetitively inspect installation of the intercooler outlet and inlet hose assemblies for any displacement or damage of clamps or hoses, and, if necessary, replace any damaged clamps or hoses.

This proposed AD results from a report of two instances of induction hose disconnection occurring while in service, resulting in a loss of turbo boost and engine power. This failure could lead to an inability to maintain altitude in flight.

One reason we brought this one up is to make sure that you are aware that any STC mods you may have in mind are also researched as well. Nothing is immune from an AD so be careful.

There are sections on ADs that have been revised as well as what you may think is an old AD that turns out to be a recurring AD for the life of the airplane. It's hard to overestimate the need to thoroughly check out this section. Often a plane has no problem, but others may be recurring and costly repetitive traps.

Also, be aware that you can look up a specific model airplane so you won't take forever in the search process. As an example we checked out the 182K model and found there are 28 ADs on this specific model.

Some of these are old, but still valid and others are new such as 11-10-09 seat track wear, which supersedes the older 87-20-03 R2 that covers the same subject. Be sure that your AD note search includes All series for engines as there are AD notes that may apply to the installed engine that are not referenced to a specific engine model.

Take a look at the reference to TCM all series where AD 96-12-22 (oil filter assembly adapter nut) is listed. This Cessna aircraft part can be installed on many different models of TCM engines and even though it is listed under TCM engines these were installed on Cessna and other aircraft (Beech, Piper and Bellanca etc) with TCM engines.

Appliances must also be checked for AD notes as there are some costly AD notes that apply to turbochargers, fuel injection systems, fuel pumps, and even air filters. AD notes against your aircraft, engine, propeller, or appliance that are not complied with intentional or not will make your aircraft un-airworthy.

This article original appeared in the May 2014 issue of Light Plane Maintenance magazine.

Read More from Light Plane Maintenance, and learn how you can receive your FREE copy of 40 Top Maintenance Tips!