Motor Head #15: Great Shakes — On The Inside Of Prop Vibration Testing

This month’s Motor Head column needs this disclaimer: Don’t try this at home! AVweb’s Marc Cook got to see what happens when manufacturers and designers have to test new propeller/engine combinations.

I subjected my still-new (and barely broken-in) Barrett-built IO-390-X to the kind of abuse that would make the old pelican himself, John Deakin, stand up in a crowd and shake his fist at me. I ran the cylinder heads to a temperature that would make any half-smart metallurgist cringe. I flogged my four-banger in a way that even old man Barrett, himself no stranger to taking an internal-combustion engine to its limits (and a bit beyond, when necessary), would consider inappropriate. I can see him cornering me at the next airshow, placing hand on shoulder and saying, "Son, I wish you hadn'ta done that."But, but, but ... I did it for science.Moreover, I did it for an education on the hows and whys of prop vibration. See, I submitted my homebuilt Sportsman 2+2 to five days of testing with Hartzell Propeller to learn if the big four-cylinder engine could get along with a new-design, blended-airfoil prop. Any pilot can tell you there's more to mating an engine and prop than making sure the studs fit through the crank flange. But, after flying a dozen flights and watching two Hartzell engineers at close range, I can tell you there's a lot more.

What's the Deal?

All props and engines face distinct challenges in getting along. Certain engines create certain kinds of vibration, from big pulses down in the 1P range (sometimes called "one per," or one beat per crankshaft revolution) as well as fractional thumps. The terminology can be confusing, it's true, but any excitation that happens once per crankshaft revolution is colloquially known as a 1P -- but more accurately called a first-order vibration. A pulse that occurs twice for every revolution of the crank is a second-order vibration, and so on. The lower the frequency, the more this vibration will feel like a rumble. There are also harmonics that go well up the range, and these are the ones that hurt metal propellers most.The trouble starts when the prop and engine combination exhibit resonances -- where a vibration created by the engine sets up a sympathetic vibration in the propeller. Think about this: The engine is creating all sorts of vibration types, low and high frequency, regular and irregular. You have natural imbalances in rotational parts, inherent imbalances in reciprocating parts, and then you have variations in the size, duration and timing of each power pulse. Change the power setting or mixture strength, and you've changed the vibration structure as well.The goal is to get the engine's and prop's natural frequencies far enough apart that they never coincide during normal operation. Doing so may require modifications to the prop, either its static balance, mass distribution, or, more commonly, by selecting a thicker blade that not only has a different natural frequency than a thinner one, but also is capable of taking more of a pounding.Hartzell's literature offers an interesting observation: If the point of high stress is at 10 or 12P (cycles per crankshaft revolution), the total number of stress cycles can add up rapidly. At 10P and 2500 rpm, it works out to 1 billion cycles in 667 hours of flying. Cyclic stress at 1P for the same amount of time is, obviously, one tenth of that, theoretically prolonging the life of the blade and hub by a like amount.

You Don't Know Until You Try

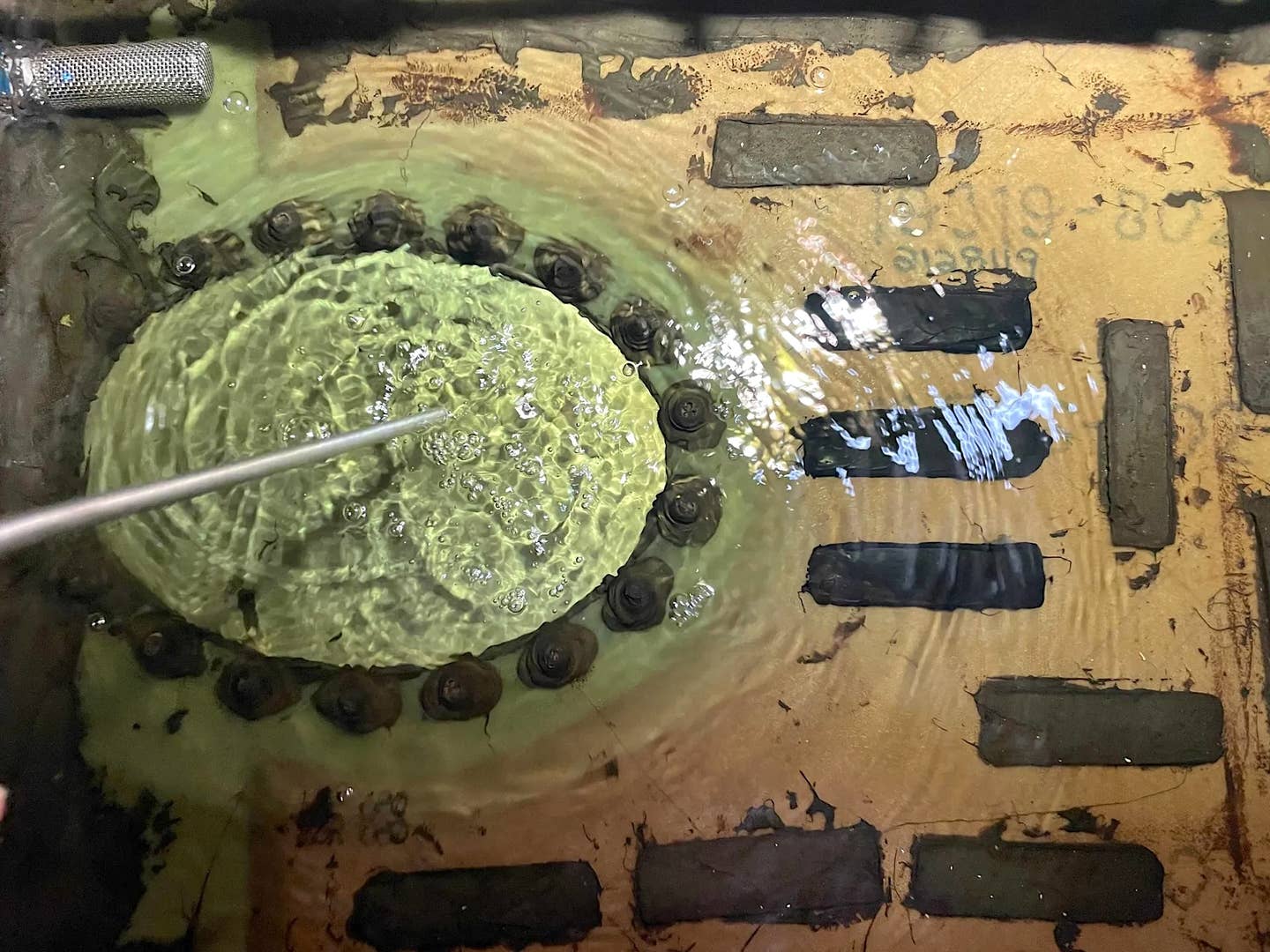

It's obviously important to test an engine/prop combination for dangerous resonances. For production aircraft, this takes place during flight testing -- and can be committed on already certified aircraft when there's a prop change on an STC, for example. But for Experimentals, it's a bit more loose. Many of the larger kit makers will offer demonstrator or prototype aircraft for testing, but not all do. Those manufacturers who decline often hide behind the fact that the builder is really the airplane manufacturer, and as such he's responsible for the happy marriage of all the parts. When it comes to recommendations, these kit makers usually err on the conservative side and only recommend engine/prop combos that have been tested in production aircraft. (That accounts for many of the big variables, but still the homebuilder's penchant for running higher compression ratios or electronic ignition inserts another layer of variability that could be of minor consequence, or huge.)That's a long way around to how I got roped into torturing my engine. Glasair Aviation, maker of my kit, was hot to get the newly released IO-390 into more of its Sportsman airframes. Hartzell was hot to know if its new blended-airfoil prop would work on the IO-390. As I was the first to fly this airplane on this engine, all eyes turned my way, like I'd belched at the opera.Hartzell was pretty dang sure the prop would work, but needed a testbed to be sure. That's how, this spring, Lee Riedel and John Hartmann showed up at my hangar in Chino, Calif., packing several magic crates and two specially prepared propellers. The goal was to test both the new prop, a 74-inch model intended for faster airplanes, as well as a more conventional 80-inch, two-blade prop that's been a popular choice for the Sportsman airframes going on floats.It took Lee and John all of the first day to prepare the airplane for ground and flight testing. And that's taking into account that much work had been done back at Hartzell's Piqua, Ohio, base: These props had been treated with dozens of film strain gauges, about a quarter inch long and an eighth-inch wide. Typically, they are bonded onto various surfaces and buried in the shank of the blade as well as the hub. Hairlike wires extend toward the hub under a thin coat of epoxy. Their placement is the result of thousands of hours of test data as well as computer modeling showing where the highest stresses are likely to be found.Signals from the tiny strain gauges are collected at special doughnut-shaped component surrounding the normal prop dome, ahead of the blades. Inside are parallel analog-to-digital converters, a matrixer and a simple RF transmitter. It's all battery powered and doesn't even have to touch the airframe. (This system is, I'm told, a massive improvement over transmitting by slip rings, which were prone to wear and had a limited number of channels.) This system can send 16 channels of data simultaneously but, typical of engineers, they want to measure more than that. So some tests are performed twice to rule out high vibration from areas where it's not expected; the bulk of the testing is done with the sensors active in the worst places, notably the mid span of the blade.On the cowling side of the prop is a simple wire antenna and a pickup that proves a once-per-revolution count for the system. We ran the wires back along the cowling under aluminum tape and into the cabin through a ventilation duct. Although the team uses a laptop to gather and examine the data, a parallel stream is sent to a 60-pound data collector with a tape drive.

First Test, Big Fun (But Not For The Engine)

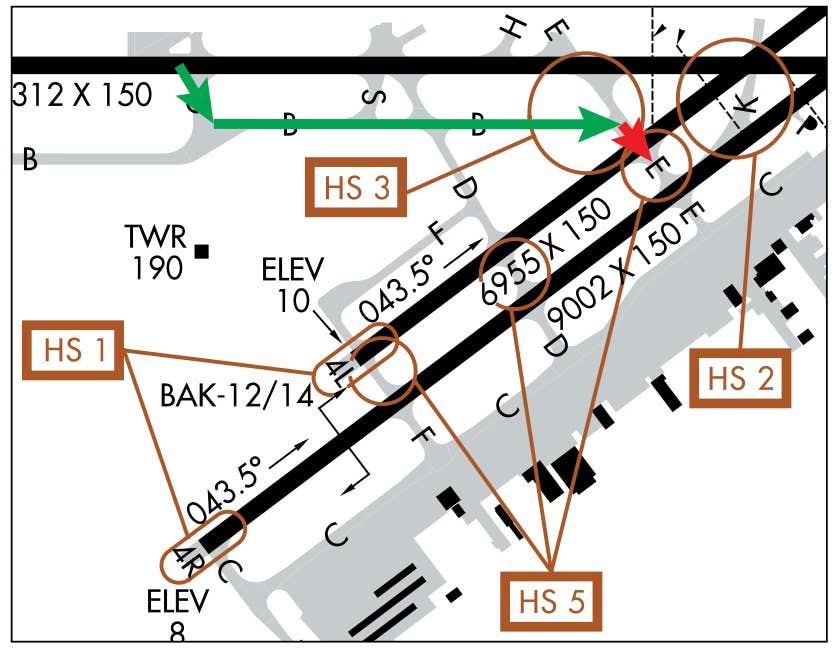

The first test is done on the ground, preferably with the airplane facing into the wind. We tied the airplane to my pickup truck so it wouldn't careen down the ramp and, with the data recorders going, ran the engine from idle to redline-plus-50 in 50-rpm increments. Engine speed for this test is by throttle only, so the power load and cooling requirements are fairly modest. (Aside from the fact that my engine doesn't idle for diddly between 900 and 1200 rpm, it was a piece of cake.)Next comes the full-throttle test. Start with max power (again at redline plus 50 rpm) and work down to 2000 rpm using the prop governor. This would be the most stressful part of the testing -- for me. We managed to keep the peak CHTs to around 420F, a number that had until that time never been reached, and has not been seen since.With the torturous ground tests done, we began the more exciting part: flying. Hartzell's test program consists of two primary flight tests, with a handful of smaller tests, to check for harmful vibration. To examine for the influence of the power pulse, one test is committed at as low a level as is safe, thereby obtaining maximum power. This one, I have to say, was a hoot, scampering along at approximately 2000 feet with the throttle pinned and the prop howling 50 rpm above redline. (I wish I could have heard that one, with the big prop, from the ground. "Cessna 185 ... incoming!") From that initial data point, the test requires a reduction of engine speed in 50-rpm increments all the way down to 2000 rpm. Assuming care and precision of the pilot in finding the correct settings, this test can go quickly. A similar version of this test is performed at 10,000 feet.Other tests include checking the takeoff and initial climb at all normal flap settings, and checking the climb-power test at all normally used engine speeds. (We did this one from 2400 to 2750 rpm.)Finally, and likely the most enjoyable test, was what is called the gas-pressure test. It's designed to measure vibration with the prop driving the engine. Begin at 10,000 feet, set max rpm with the governor, completely close the throttle ... and then pitch over until the prop comes up to the redline value. For the small prop, this wasn't a harrowing test, but with the drag of the 80-incher, Lee and I were looking nearly straight down to California soil before the prop got to speed. Then it's a modest pitch-up to the stall. Simple.After the test, Lee checks for scary vibration peaks on the laptop. For the small prop, we found none. For the 80-inch jobbie, he noticed a definite resonance. (In fact, he had predicted it. Smart guy.) So we repeated the test with a bit of throttle. And then again with a bit more throttle, to isolate the minimum manifold pressure required to keep the prop out of the danger zone. After three tests and lots of good data, we were done.Five days of testing later, Lee and John packed up their equipment and took the two instrument props back to Ohio. Normally, they work separately, but there was something of a push to get my airplane tested, and, in particular, two props tested at the same time. I can't say enough about their efficiency and professionalism. And it was tested: Over a plate of steaming cobbler at Flo's Cafe, I asked John about the scariest test flight he'd ever been on; c'mon, tell us all about it. He pondered the question in that slightly distracted, engineer way, cracked the slightest smile and confessed, "I'd better not say." Denied! I just hope that when he retires and can spill the stories, John won't mention me by name.

Got motors on your mind? Check out the rest of Marc's columns.