The Savvy Aviator #31: Know Your Oleo

Oleopneumatic shock struts — commonly known as “oleos” — use hydraulic fluid, compressed gas and clever engineering to absorb the impact of those occasional less-than-grease-job landings. If your airplane uses one (or three), you need to understand how they work and what maintenance they require.

If every one of our landings were a perfect "grease job" where the mains kiss the runway at an infinitesimally small descent rate -- and if every runway we land on were a perfectly smooth surface without any bumps or potholes -- then the landing gear on our airplanes could be dead simple. Wheel assemblies rigidly attached to the airframe would work fine, just as they did on the toy wagon and roller-skates I had when I was a kid.Dream on!In the real world, some of our landings ("arrivals"?) involve embarrassingly firm touchdowns. Some of the runways and taxiways we use are not exactly pool-table smooth, either. Which is why nearly every airplane ever built has been equipped with a shock-absorbing landing gear designed to survive considerable abuse.Lightweight aircraft can often get away with a simple, spring-loaded gear. Many older tube-and-fabric designs (like the venerable Piper Cub) use a simple, hinged gear leg with stranded rubber shock cords used to absorb the shock of landing. Mooneys use a stack of shock-absorbing rubber doughnuts for the same purpose.

Many aircraft designs, most notably Cessna singles, use shock-absorbing spring-steel gear legs (either flat or tubular), an elegantly simple design pioneered and patented in the 1930s by air racer Steve Wittman. Cessna licensed the design from Wittman in the 1940s, introduced it in 1946 on the Cessna 140, and has used it on its single-engine aircraft ever since. Some recent lightplane designs employ a similar spring-leg approach using composites instead of steel.

The Recoil Problem

Simple spring-type landing-gear designs like these have some compelling advantages when used in light planes. They're cheap, lightweight, require a minimal number of parts and are essentially maintenance-free. Rubber shock cords deteriorate with age and occasionally require replacement, but Wittman-type spring-steel gear legs often last the life of the airframe with no maintenance at all.Unfortunately, they also have two rather serious disadvantages. First, they don't scale very well to heavier aircraft. As the weight of the aircraft increases, the size of the rubber or steel or composite springs required to absorb the shock of landing tends to get impractically large.Second, and perhaps more important, simple spring-type gear legs aren't very good at damping the recoil of a hard landing. The harder the landing, the more energy the landing gear springs absorb, and the more energetic the ensuing recoil. The result is that a hard landing on a simple spring-type gear often results in a bounced landing -- which at best can be embarrassing and at worst can result in loss of control and damage to the aircraft.An excellent demonstration of this problem occurred during Charles Lindbergh's historic New-York-to-Paris flight on May 20-21, 1927. His custom-built Ryan NYP monoplane was adapted from Ryan's M-2 Mailplane, which used a shock-cord-type landing gear like most aircraft of its day. But the custom-built NYP carried 450 gallons of fuel and had a maximum takeoff weight of 5,250 pounds -- nearly twice that of the M-2. The gear of the NYP still used shock cords, but was massively beefed up to support the additional weight.The result was obvious to anyone who has seen the old motion picture footage of Lindberg's takeoff from Roosevelt Field, N.Y., and his landing at Le Bourget Field, Paris. The takeoff was a heart-stopping sequence of bounces (the muddy turf runway probably didn't help) that almost ended in disaster. The landing was also badly bounced (more than 33 hours without sleep probably didn't help).Both the takeoff and landing were excellent examples of the recoil problem inherent in simple spring-type landing-gear designs. As aircraft got larger and heavier, a more forgiving landing gear design became a necessity.

Enter The Oleo

The answer was the oleopneumatic or "air-oil" shock strut, originally introduced in the late 1920s by the Cleveland Pneumatic Company. Cleveland's "Aerol" strut quickly gained acceptance in the 1930s, and was the landing gear technology of choice by the time aviation exploded in the 1940s, transforming Cleveland Pneumatic Aerol into one of the nation's largest wartime industrial companies.The "oleo" strut uses compressed air or nitrogen combined with hydraulic fluid to absorb and dissipate the shock of landing, and to damp the recoil to minimize bounced landings. The strut consists of two telescoping tubes with externally closed ends. The upper type is historically referred to as the "cylinder" and the lower tube as the "piston" (for reasons that aren't entirely obvious).The two telescoping cylinders form a variable-displacement chamber that contains hydraulic fluid on the bottom and compressed air or nitrogen on the top. As the strut is compressed during landing, the incompressible hydraulic fluid maintains constant volume, while the gas at the top of the strut is compressed to smaller volume and higher pressure. The compressed gas acts as a spring, and performs the same function as the shock cord or spring steel of a simple spring-type gear.The bottom of the upper tube ("cylinder") is equipped with a high-pressure seal to prevent fluid or gas from escaping from the chamber as the strut compresses and extends. For light-duty shock struts, the seal may be a simple O-ring; for heavier-duty struts, it tends to get a bit more exotic. Just below the seal is a scraper ring whose purpose is to prevent dirt and other foreign material from damaging the seal as the strut compresses. The seal and scraper ring are typically retained by a snap ring.

Taming The Bounce

The purpose of the "oil" (actually, hydraulic fluid) in an oleo strut is to damp the action of the gas "spring," slowing the rate at which the strut absorbs landing shocks, and slowing the post-impact recoil to minimize the chance of a bounced landing.To accomplish this, the strut is equipped with an orifice plate that divides the lower fluid-bearing part of the strut into two chambers. As the strut compresses during landing, the fluid is forced through the orifice from the lower chamber to the upper one, and as the strut extends during post-landing recoil (or takeoff), the fluid is forced back through the orifice in the opposite direction. The size of the orifice and the viscosity of the fluid limits the rate at which the strut can compress or extend.Now here's where things get really clever. Most oleo struts employ a tapered "metering pin" to vary the effective size of the orifice and therefore the rate of fluid flow from one chamber to the other. The more the strut compresses, the tighter the orifice becomes, and the more resistant the strut is to compress or extend.The result is a landing gear that starts off very soft at touchdown, and becomes increasing stiff as the strut compresses and the energy of landing is dissipated. When near-fully compressed after landing, the strut is highly damped and recoils slowly and with great reluctance. (It even makes my landings look good!)While the metering pin gradually tapers from bottom to top, it normally has a larger-diameter "bulb" at its extreme upper end. The purpose of this odd-looking swelling is to slow the extension of the strut on takeoff just as it reaches full extension, thus minimizing the rate at which the strut hits its mechanical stop after liftoff. (Never underestimate the cleverness of a mechanical engineer from Cleveland!)

Design-A-Strut 101

The design of an air-oil strut is more complex than you might imagine, and some of the engineering considerations are quite interesting.Take gas pressure, for example. A widely-used rule-of-thumb is that the compression ratio of a main-gear oleo strut should be about 4:1 between the fully-extended and static (taxi) position, and about 3:1 between the static and fully-compressed position.The latter figure comes from FAA certification requirements, which require that a landing gear be designed to handle a hard landing with a sink rate of 10 feet/second (or 600 FPM). A simple calculation shows that for a main landing gear strut with a typical maximum throw length of 12 inches, the required deceleration from such a landing is about 3g. Thus, the strut needs to be able to dissipate a worst-case landing force equivalent to about three times the aircraft's normal static weight.There are a number of other constraints on gas pressure. If the minimum pressure in the strut when fully extended is less than about 50 or 60 psi, the o-ring seal at the bottom of the cylinder may not seal tightly enough against the chrome-plated piston to prevent the strut from leaking in flight. Conversely, if the maximum pressure in the strut when fully compressed is more than 5,000 or 6,000 psi, the seal might blow out on a hard landing. Finally, if the pressure in the strut in its normal static position is more than about 1,500 psi, it will be impossible to add gas to the strut without jacking the aircraft (since nitrogen bottles typically have a maximum pressure of 1,800 psi when absolutely full).Given these constraints, a working pressure of about 1,200 psi under static (taxi) load is a good compromise. At full extension (with a 4:1 compression ratio), the pressure drops to about 300 psi -- plenty to maintain a tight O-ring seal with the strut unloaded. At full compression (with a 3:1 compression ratio), the pressure rises to about 3,600 psi -- easily handled by the seals with little risk of blowout.Given a static pressure of 1,200 psi, the required strut diameter can be easily determined based on the weight of the aircraft. For example, my Cessna 310 twin has a maximum weight of about 5,500 pounds, which means that each main gear needs to support roughly 2,500 pounds under static conditions (with the nose gear supporting a bit as well). At 1,200 psi, this requires a piston cross-sectional area of a bit over 2 square inches, which translates into a piston diameter of about 1.7 inches.

The fully-extended gear has a throw of about 12 inches. At a 4:1 compression ratio, the static extension is about three inches. In a hard-landing scenario -- say I forgot to flare and drove the airplane on at a 600 FPM sink rate -- the strut would theoretically compress to about 1-inch extension with an internal pressure of 3,600 psi (3:1 ratio) and an opposing force of 7,500 pounds. (Not that this would ever actually happen to my airplane, mind you.)A typical nosegear oleo handles a lot less weight, and has a shorter throw and lower working pressure. But its ability to dampen landing shocks with minimal recoil is perhaps even more important than for a main gear. Consider that a nosegear recoil pitches the nose up, increases the wing angle-of-attack, causes the airplane to want to start flying again -- and can easily lead to divergent pitch oscillations (often referred to as "PIO" or "pilot-induced oscillations") that have been known to wrinkle firewalls, curl prop tips, snap off nosewheels, and generally give owners a bad hair day.That's probably one reason that although many tricycle-gear airplanes (notably single-engine Cessnas) still use the simple Wittman-type spring gear for their mains, they use an oleo strut on the nose to help prevent such porpoising.

Strut Inflation

Your aircraft's service manual provides detailed servicing instructions for your oleos. Typically, a specific inflation pressure is given for servicing the strut when it is fully extended (i.e., airplane on jacks), and a strut-extension measurement is given for "airing up" the strut with the aircraft "on its feet." These same servicing instructions are also contained on an FAA-required placard affixed to each strut. (If you lost your placard when your plane was last painted, your IA should insist that it be replaced before signing off your annual.)For example, the main gear struts on my 1979 Cessna 310 are placarded for a no-load inflation pressure of 320 psi, and for a static-load extension of 3 inches. For the nose strut, the corresponding figures are about 50 psi and 1.5 inches.But there's a real trap here. Suppose you notice that your strut extension is a bit lower than it should be. The temptation, of course, is to "air up" the strut a bit (using a nitrogen bottle or strut pump) to bring it back up to the specified height. Before you do this, stop and think about it for a moment. How do you know whether the strut extension is low because it needs more air/nitrogen pressure, or whether it's low because it needs more hydraulic fluid?If the strut is actually low on fluid (because some seeped out past the o-ring seal between the cylinder and piston) and you compensate by adding air/nitrogen, then what you've done is to lower the compression ratio between static and fully-compressed positions of the strut. Repeat this a few times and you might wind up with a strut that's sufficiently short on fluid and long on air that it'll physically bottom out on a hard landing -- and that could definitely be a bad thing (read $$$).Remember that the function of air or nitrogen in an oleo is to provide the strut's spring force, and the function of hydraulic fluid is to provide the strut's damping force. Consequently, a useful test is to rock the aircraft by applying an up-and-down force at a wingtip or at the prop (depending on whether you're interested in the main or nose oleo), and see how the strut reacts. If the strut bounces up and down freely with relatively little damping, then it's most likely low on fluid. If the strut moves stiffly and shows little willingness to bounce, the fluid level is probably adequate and the strut may just need a little air or nitrogen.If there's any indication that the strut may be low on fluid (i.e., it's "bouncy"), you should definitely check the fluid level in order to preclude the possibility of damage during a firm landing. Low fluid is potentially a lot more serious than low air.

Servicing The Strut

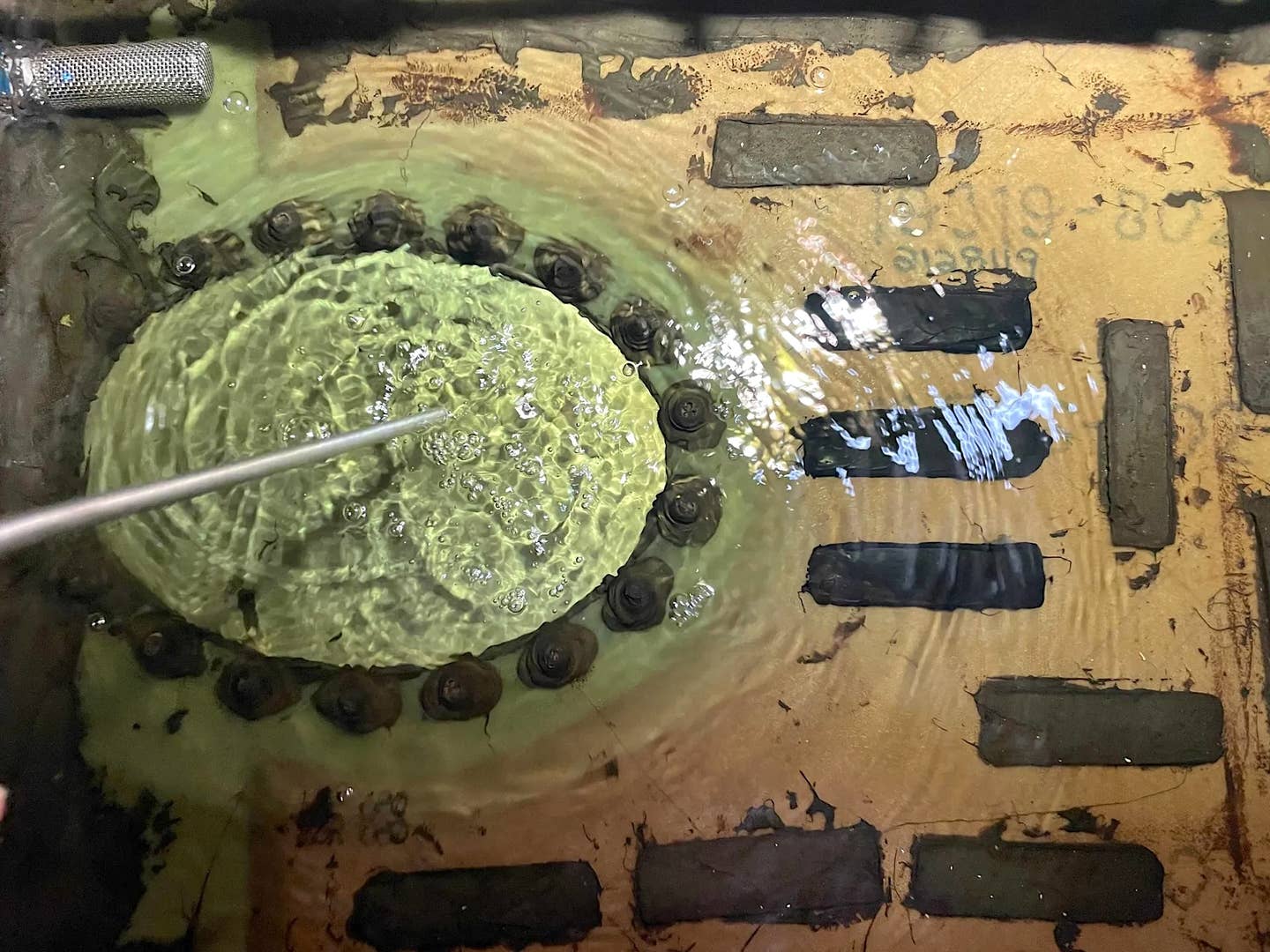

Servicing of oleo struts is a preventive maintenance task that an owner/operator is specifically permitted to do without needing A&P supervision or signoff. But it's important to know what you're doing before you tackle this for the first time.To properly service an oleo strut, the aircraft must be jacked until the strut is fully extended and the wheel is off the ground.Then fully deflate the strut, using the fill valve located at or near the top of the upper strut. To deflate the strut, remove the valve core if there is one (using an ordinary automotive valve core tool), open the valve using an end-wrench and allow all the pressure to bleed off.Slide one end of a tight-fitting, two-foot length of clear plastic tubing over the filler valve stem, and immerse the other end of the tubing into a pan of MIL-H-5606 hydraulic fluid. Slowly compress the strut fully to expel additional air and any excess fluid. Then slowly allow the strut to extend strut fully, which will suck hydraulic fluid from the pan through the tube and into the strut.Repeat this compress/extend process several times. Each time you extend the strut, it will suck fluid up the tube and into the strut. Each time you compress the strut, it will expel air that is entrapped in the fluid (plus excess fluid) into the pan. Continue pumping the strut up and down slowly in this fashion until you've eliminated as much entrapped air as you can, and the expelled fluid comes out relatively free of air bubbles.At that point, compress the strut fully once more (to eject excess fluid), then remove the plastic tube from the valve stem. Extend the strut fully, allowing it to suck in air this time. If you removed a high-pressure Schrader core from the valve, reinstall it now. Then service the strut with dry compressed air or nitrogen to the recommended pressure. (You'll find that pressure in the service manual, and should also find it on the required placard affixed to the strut itself.) Then close the fill valve with a wrench and install its protective cap.It's important that the strut be completely topped with fluid when it is fully compressed, and that the fluid have as little entrapped air as possible. The procedure just described will assure this.I've used the terms "air" and "nitrogen" interchangeably in this article. Inflating a strut with a nitrogen bottle is preferred because bottled nitrogen is virtually moisture-free. Compressed air is an acceptable alternative provided the air is known to be dry. In transport and jet aircraft, servicing with nitrogen is required because the struts dissipate so much heat during landing that dieseling of the hydraulic fluid can occur if there's oxygen in the strut. With small piston aircraft, however, this is not an issue.After the strut has been serviced, remove the aircraft from jacks, rock the just-serviced strut up and down, and check that the strut extension is reasonably close to the static extension values given in the service manual and on the strut placard. A little variation is OK -- in fact, you should expect a little if the aircraft is particularly light on fuel or heavy on payload at the time. But if the strut is significantly under or over the recommended static extension, you might consider adding or removing a little air or nitrogen.

Strut Re-Seal

If an oleo strut has a tendency to lose height, or if it starts "weeping" any significant amount of hydraulic fluid, it's probably time for a re-seal. This does require the services of an A&P, but it's not as scary as it sounds, and generally involves no more than a couple of hours' labor and perhaps $20 worth of parts.Basically, the aircraft is jacked and the strut deflated just as described previously. Then the snap ring is removed from the bottom of the upper strut, the bolt is removed from the knuckle of the torque links ("scissors") and the lower strut is pulled completely free from the upper strut, dumping a whole bunch of sticky red hydraulic fluid into the pan that was artfully positioned to catch it.With the strut disassembled, all the o-rings and other seals are replaced with new ones. Then the strut is carefully put back together (taking care not to damage the new seals), the snap ring reinstalled, and the torque links reattached. Finally, the strut is serviced with fluid and gas as described earlier. Presto -- a leak-free strut.If you're the curious type, you might want to arrange to hang around and watch (or help) while your mechanic does this. It'll give you a good opportunity to examine the metering pin, orifice plate, seals, and the numerous other goodies concealed within the guts of your oleo. With any luck at all, you won't get another chance to eyeball them for another five or 10 years.See you next month.

Want to read more from Mike Busch? Check out the rest of his Savvy Aviator columns.