The Pilot’s Lounge #143: Service Test Flying

There are three levels of flight testing. The top end, requiring extensive education and training, is experimental flight test. The next level down is production flight test. Service test flying is the lowest rung on the test ladder. It usually can be carried out by any pilot knowledgeable in the type of aircraft involved and who has some degree of experience and decent judgment.

It was my Sunday morning to pick up the doughnuts on the way to the pilot's lounge at the virtual airport, so I wanted to get there early. If it's your doughnut day and you show up after the regulars are already ensconced in the ratty old recliners, swilling coffee and telling flying lies, you're going to be on the receiving end of enough verbal abuse—even if good-spirited—that you'll take doughnut duty seriously in the future.

I thought I'd be the first one there—I'd been mentally reviewing the steps need to coax the aging coffee maker to life as I walked down the hall—yet the light was already on and I could hear conversation. To my amazement, our favorite curmudgeon was there, wrapped up in a blanket and sitting in one of the recliners. He was growling instructions for operating the coffee maker at Karver, one of our newer regulars. To say that I was surprised to see Hack is an understatement. His health has slipped to the point that he'd been transferred into the care wing of the assisted living facility where he lived. He's a legend around here—he bought a Piper Super Cruiser nearly new and flew it with elan until he was in his 80s. He knew every landmark within 20 miles and would scud run to get where he needed to go until cellphone towers started popping up, and then surprised everyone by getting his instrument rating when he was in his 70s—and then his multi-engine rating. The last time I'd visited I came away convinced that he'd made his last trip to the airport.

Hack noticed the astonished look on my face, interrupted his unneeded directions to Karver and said, "What's wrong with you, boy, don't you have the manners to say ‘hello' when you walk into a room?" Hack looked like a shriveled-up version of himself, but the voice that could peel paint at any distance was still in full bellow.

I sputtered out a stream-of-consciousness greeting, allowed as how I was glad to see him and surprised to see him.

He grinned, "Yeah, I leaned on the kid and convinced him to bring me out here for one more Sunday morning with the riffraff. It turned into quite a production. I'm not supposed to leave that damn prison they call a hospital, so Karver smuggled me out. I haven't had this much fun since I changed the lock on your hangar door."

Further conversation was interrupted by a steady stream of pilots and student pilots walking in the door. I put the box of doughnuts on the counter and watched it draw pilots like flies on carrion. I found an unoccupied chair about the time the coffee was ready and settled in to enjoy good talk with good people.

About 10 minutes later Old Hack's voice, directed at me, cut through the ambient noise. "Hey, Rick, wake up. Karver here was asking about service test flying and nobody here seems to know what it is. You did some of that stuff, didn't you?"

"Yeah, but it was more than 30 years ago, and nobody'd be interested."

"Nonsense, there's not nearly as much call for it as there was back then, but it's kind of unusual, was flying that you really enjoyed—as I recall—and it's an interesting little corner of aviation. So, man up and talk."

So, I did. I saw Karver making notes. After he was done, I borrowed them to write this because, well, service test flying has long been an opportunity for a pilot in the right place at the right time to do some interesting flying that is a bit out of the ordinary.

Flight Test Hierarchy

There are three levels of flight testing. The top end, requiring extensive education and training, is experimental flight test. Those men and women take airplanes that are either entirely new or have significant modifications into the great wind tunnel in the sky to see if the design engineers have done their sums right. It is the riskiest form of test flying.

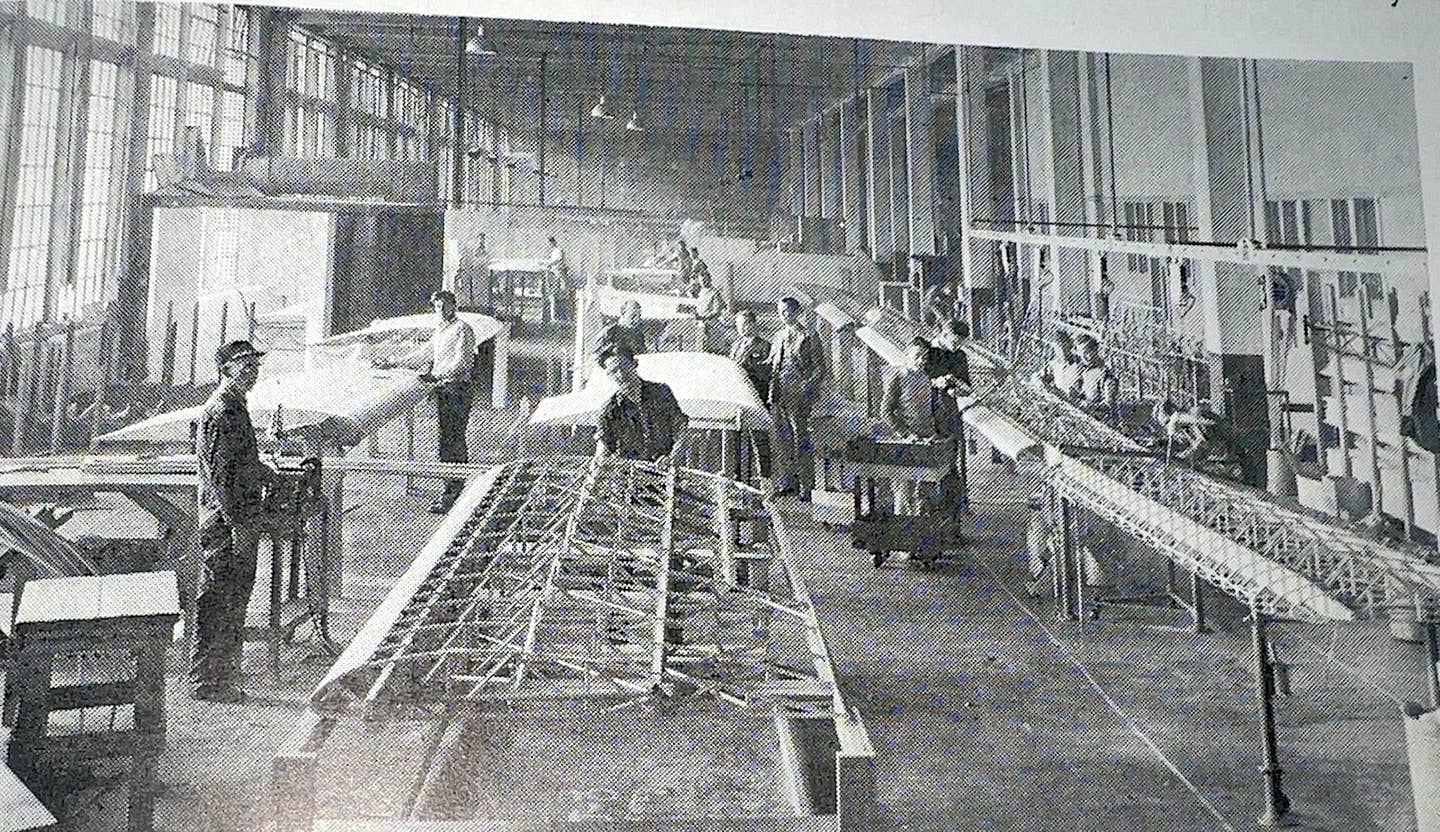

The next level down is production flight test. Those pilots make the first few flights of airplanes after they roll off of the assembly line. It requires specialized training in accurately obtaining performance data and evaluating systems efficiently. Most of my friends who flew production flight test liked it, but said that when the weather was good, their worst enemy was boredom. In the seven years that I worked for an aircraft manufacturer the worst thing that happened on a production test flight—that I learned about—was a situation where the gear wouldn't extend, and the pilot had to slide the airplane to a stop.

Service test flying is the lowest rung on the test ladder. It usually can be carried out by any pilot knowledgeable in the type of aircraft involved and who has some degree of experience and decent judgment. In the military, service test often involves making the flights of aircraft coming out of maintenance to assure that everything was put together correctly—which is sometimes not the case. Information I received from military pilots and my own experience with airplanes coming out of the shop (total electrical failure on one first flight, gear wouldn't retract on another) caused me to make a hard and fast rule that the first flight I make of any airplane fresh out of the shop is day VFR with no passengers.

A late friend of mine flew combat in P-400s and P-38s in World War II. Nearly half of his flying time was service test and engine break-in because the Allison engines in those airplanes would rarely last more than 40 hours in service, so they were constantly being changed and the fighter pilots had to spend five or so hours "slow timing" the new engine for break-in before the airplane could be flown in combat.

In the general aviation world, when a manufacturer develops a new airplane, its experimental test pilots put it through the extraordinarily involved flight tests required to meet FAA certification (and the company in-house requirements that may exist on top of the FAA regs). However, most companies also want to find out how the airplane is going to hold up in service. What is going to break? Are there weak spots that may only show up after a few hundred hours of operation? To find out, those companies will set up what is known as an accelerated service test program. It usually starts before the certification process is complete. When I worked for Cessna in the late 1970s and first half of the 1980s, once the engineering folks were reasonably sure that the new design would complete certification so that the prototype airplanes were in their final or "confirming" form, one prototype would be dedicated to the accelerated service test program.

I was involved in three accelerated service test programs. The first was a little different. The T303 Crusader was in development and was going to use a new version of the Continental TSIO-520 engine—the AE, developing 250 HP. Cessna obtained an older 310, pulled the 240-HP IO-470 engines off and installed the engines and cowlings that it was going to hang on the T303 and put the word out within the company that it needed pilots with a certain level of experience for a service test. I checked with my boss and got approval to get involved. The program was as it was for most of the tests I later flew—for turboprops there was significant classroom time to learn the new airplane, for pistons there was one-on-one ground time with an instructor and then a checkout. Once the needed pilots were checked out, there was an attempt to fly the airplane as much as possible—all day and all night. Depending on the airplane there would be four- or six-hour blocks of time. For the T303 engines, T303 prototype and 208 Caravan prototype the pilot would sign up for a six-hour block. (There would also be blocks set aside for scheduled maintenance and inspections.) When it was my turn, I would meet the incoming pilot, usually while he or she was wrapping up fueling the airplane, doing a post-flight inspection and filling out paperwork. I would talk with the pilot about his or her flight and do my preflight. I sometimes had an assigned profile that I was to fly or a choice of profiles. From time to time I could do whatever I wanted so long as I did a minimum number of landings—usually with maximum braking and prop reverse (if applicable). The flight should be set up to be as long as possible while returning with sufficient fuel reserve to meet the FARs and the pilot's personal minimums.

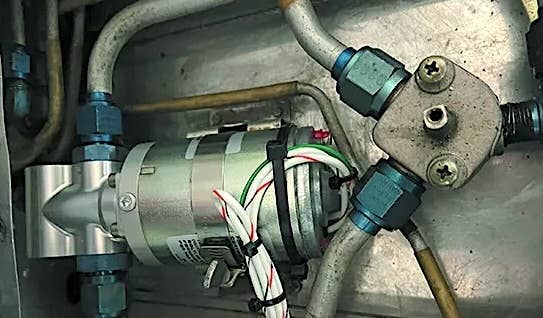

For the T303 engines the head of powerplants in the engineering department had told me that he was frustrated because the service test pilots weren't taking the test bed up high. So, on my first flight I filed IFR to somewhere in Iowa at FL230. As I was passing the Topeka area, the left engine started running rough. Staring at the cowling didn't help. Turning the aux pump on didn't help. Trying different mixture settings didn't help. A mag check didn't change anything. The roughness got worse. I decided that now was a good time to head back to Wichita and write up the problem, although being prepared to shut down the engine on the way was front and center in my thinking.

I told ATC that I had an unidentified problem and was going to return to Cessna field. Having a Cessna test call sign always seemed to mean fast responses from ATC. I aimed the airplane southwest and started a descent. Going through about 15,000 feet the engine smoothed out and ran perfectly all the way back to the ramp. Taxiing in, I wondered whether I'd just imagined the problem and thought I might not have the right stuff to do this kind of flying.

My report grounded the airplane, so I was really concerned that I'd screwed up the test program. It wasn't long before the head of powerplants wanted to talk with me. I explained what I'd experienced. To my astonishment, he was pleased. He said that he'd been concerned about the performance of the mags they were using at altitude. He thought there was a risk of cross firing (or high-altitude misfire)—a condition where the mag shorts internally due to the loss of the insulating effect of air. That results in the mag sending electrical impulses to the spark plugs at the wrong times, potentially causing loss of engine power at best or detonation and destruction at worst. I'd apparently been the first one to take the airplane into the flight levels.

I do not know what changes were made, but my subsequent ascents beyond the high teens with those engines were without problems.

T303

As the T303 neared certification one of the three (as I recall) prototypes was pulled aside for an accelerated service test and a number of Cessna employees volunteered to fly the bejabbers out of it. Following my checkout, I flew the airplane as often as I could. I don't recall details of the profiles other than one of them was long flights on IFR flight plans, with approaches, to simulate owners who used their airplanes for travel, and one involved maneuvering and numerous takeoff and landings as well as shutting down and doing hot starts to simulate use at an FBO for training and rental.

To my knowledge, the test airplane had every possible option installed. The radios were top of the line as was the radar, interior appointments and, to my fascination, a cassette tape player with an interrupt feature that stopped the music when ATC called. While that sort of thing is common now, it was cutting edge then. It was pretty cool to listen to Bruce Springsteen at max volume while shooting an instrument approach in the clag.

I purely had a ball flying the T303. It was, and still is, the nicest-handling piston twin I'd ever flown. It was a Dave Ellis design—he was the genius Cessna had hired to run the advanced design department for the Pawnee Division. His eye for stability, control and handling was, in my opinion, unmatched in the general aviation world. Vmc for the T303 was so slow that the airplane would probably stall before directional control was lost if a pilot screwed up and got slow following an engine failure. It could safely be flown and tossed around in the traffic pattern at a speed 20 knots below the minimum I was used to holding in other piston twins. That paid off one afternoon when I shot the VOR-A approach into Cessna Field to published minimums and easily circled to land because it was safe to slow the airplane down for maneuvering in restricted visibility.

I never had a problem with the airplane on any of my flights in the T303, including going into some pretty short fields in rural Oklahoma. I did discover that Dodge City, Kansas, does not exist. On two different flights I shot the published ILS into what was supposed to be Dodge City. On each trip I descended to decision altitude and looked out. There wasn't anything to be seen. The world was gray in all directions. I missed the approach and flew on to places that did exist.

208 Caravan

When time came for the service test program on the 208 Caravan, I was a little concerned. Frankly, the pilot sat so high that I wasn't sure I could figure out when to flare on landing.

I attended the training class and was amazed at how brilliantly simple the airplane was. It was designed to survive operation in the bush with a minimal number of things that could break. The checkout proved to be a snap. It was another Dave Ellis design, so handling was fingertip and delightful. The sight picture on approach was so similar to that of a 172 that finding the right height to flare turned out to be instinctive. The airplane was so easy to fly that I came away convinced that I could solo a student pilot in one with fewer hours than in a Cessna 150.

The service test airplane was equipped with, as I recall, 12 seats. On one flight I made I arranged for engineers who had worked on the design of the airplane and hadn't ridden in it to go along. I filled the seats and headed for Millard, Nebraska, on an out-and-back profile. During each leg the engineers (none of them pilots) changed seats every 10 or 15 minutes so each got a chance to fly the airplane. It seemed to me that everyone had a great time.

On approach to Millard, a suburb of Omaha, the airport looked deserted. There was no one on Unicom and I couldn't see any movement on the ramp. We were just another single-engine Cessna on final to a Midwestern airport. No big deal. Until touchdown—and I followed the instructions in the profile and used full reverse. Back then single-engine airplanes didn't make reverse noises. People started coming out of the woodwork.

By the time we got to the ramp we there was a crowd at the airport fence. As we followed the guidance of the guy marshalling us to parking the engineers started encouraging me to "back it up!" The area was clear, so I reversed into the tiedown spot behind us. That got us lots of attention.

After I shut the engine down the lineman picked up a red carpet and approached the airplane, trying to decide where to unroll it—there were four doors. The engineers were like kids. They wanted to wait until the lineman put the carpet down in front of one of the doors and then go out another one. They waited impatiently. The lineman put the carpet down outside my door. Instantly one of the engineers opened the airstair door back aft and they went scooting down it. The lineman immediately scooped up the rug and ran around to place it in front of the airstair.

There were a few dozen people at the fence. They asked if they could see the airplane—and we were eager to show it off. We spent several minutes walking folks around the airplane, letting them peer inside and answering questions about it. With their detailed knowledge of the 208, I thought those engineers were some of the best airplane salespeople I'd ever heard.

Cessna 152 Lead Fouling

Not all service tests involved new airplanes. One of the considerations in the replacement of the Continental-powered Cessna 150 with the Lycoming-powered Cessna 152 was the phasing out of 80/87 octane avgas in favor of the higher lead content 100LL fuel was lead-fouled spark plugs. It was widely believed that the Lycoming engine would be more resistant to lead fouling than the Continental.

That may have been true; however, the Lycoming in the 152 had more than its share of lead-fouling issues.

To try to get a handle on the susceptibility to lead fouling of the Lycoming O-235 as installed in the 152, Cessna set up an accelerated service test. As I recall, the blocks were reduced from six hours to four because the 152 carried only about 3.5 hours of fuel. The profile was student training—touch and goes and maneuvers, no cross countries.

The big thing was that the mixture control would be left at full rich at all times—the engine would even be shut down with the ignition key (which required conscious thought at the end of a session).

The engine did suffer badly from lead fouling, but I had some enjoyable flights playing student pilot.

One of the downsides of service test flying was that the pilots generally weren't told of the results—we were bus drivers for the engineers. I don't know what was done as a result of the lead fouling tests, but when I fly a Cessna 150 or 152, I lean the mixture aggressively immediately after startup and during any time I'm flying level.

Cessna 340

If I could own afford a piston twin as a personal hot rod, it would be the Cessna 340. It's pressurized and while it doesn't have the amazing handling of the T303, it's tremendously fun to fly and goes like stink.

By the early 1980s many of the airplanes were exhibiting cracks in the horizontal stabilizer. As I recall, the problem was first felt to be cosmetic. As time went by and more information was obtained, it became apparent that the issue was structural. That is a big deal and it got Cessna's, and the FAA's, undivided attention.

The engineers designed a new horizontal stabilizer and an accelerated service test program was laid on. This one had the FAA's attention and an FAA inspector went on every flight—as I said, cracking structure is a big deal.

This was the only service test series I flew in which the pilots were required to wear parachutes.

I vividly remember much of the first flight I made. I understand that adrenalin helps that process.

The FAA inspector assigned turned out to be a guy I knew and liked. As we prepared for the flight there was an atmosphere of concern. Even I, under 30 and not smart enough to recognize danger, could feel it. With us during the preflight were some Cessna test personnel wearing lab coats. They briefed us on things to watch for and warning signs of something going wrong. They advised us that they would meet us when we returned and go about trying to stick 3 x 5-inch index cards between the rivets on the horizontal stabilizer and the skin to see if there was evidence of dangerous vibration. Apparently the first symptom would be loosening of the rivets. I couldn't seem to get too excited about the whole thing—there had been a bunch of flights before this one and all I felt was a combination of frustration over not being able to get on the schedule sooner and eagerness to fly the 340—I really liked 340s.

The cabin furnishings had been stripped out of the airplane. There was a knotted rope strung along the ceiling. It was our emergency egress system—if we had to get out, we would pull ourselves along the rope to the airstair door and do our best to egress. We both knew that on the very first flight of the Cessna 340 prototype in 1970 that the aircraft crashed, and the test pilot died. It turned out that one elevator hinge pin had not been installed—as I recall reading—and the airplane started an outside loop that could not be countered. The airplane hit the ground inverted before the pilot could get out.

I still remember the test profile—it was no holds barred: Climb at full power to 7000 feet MSL, set up cruise at the top of the green (max climb power) and fly for three hours. Then go to full power and climb to 15,000 feet. The next step was an eye-opener in Kansas summer turbulence: Slightly reduce the power to the top of the green (max climb power, remember?) and dive, holding the airspeed at redline. Smoke on down to the traffic pattern. The rest was anticlimactic—make two touch and goes and a full-stop landing.

After the flight the gentlemen in lab coat folks were able to stick their index cards under several rivets. They had worried looks on their faces. My FAA friend and I looked at each other and didn't say anything. We filled out the log, other assorted paperwork and told the lab-coat folks that we hadn't observed anything unusual during the flight.

The service test was stopped after our flight. There were working rivets and small cracks. The horizontal stabilizer was redesigned again. The problem turned out to be a harmonic vibration that was worst, as I recall, at a prop RPM of 2400. The new tail design had a different natural frequency of vibration.

I flew the same profile on the new tail design. There were no problems. I do not remember how the tail replacement program was set up to get new tails to airplanes in the field. I have flown 340s since and have friends who own them—I don't think any have had tail cracking issues. Apparently, the fix worked. The high-power, high-speed accelerated test profile performed as designed—it induced tail cracking in a matter of days, rather than years, of operation. It then apparently confirmed that the fix worked.

So, Do It

After participating in several accelerated service tests, I decided that if I'm ever in a position to buy a brand-new airplane that is one of the first of a brand-new model line, I want to make sure that the manufacturer has already put a few hundred hours on one of them before I become a purchaser. I want the manufacturer to have a fighting chance of knowing what's going to break early on.

I also decided long ago that if I ever get the chance to participate in another service test, I'll do it if I possibly can.

Rick Durden is a CFII, holds an ATP with type ratings in the Douglas DC-3 and Cessna Citation and is the author of The Thinking Pilot's Flight Manual or, How to Survive Flying Little Airplanes and Have a Ball Doing it, Vols. 1 & 2.